CT_Tree_Guy

Platinum Member

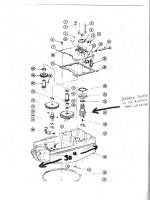

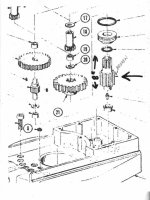

Well, I've gone and done it. I broke a large tooth off a large gear, the "pinion rotator drive" gear that rotates the turret on the Powers PM-300 6-ton crane on one of my International Loadstars.

It's made of pure Unobtainium, so it HAS to be repaired, or duplicated. Does anyone have any experience with repairing a broken tooth on a gear? It's a straight-cut gear vs. helical, so that might simplify things somewhat.

I don't know the exact composition of the gear, but it's a steel alloy of some sort, hardened. Can the missing tooth be built up with MIG or TIG, then machined, then hardened? Should the gear be softened prior to welding and machining, then the entire gear rehardened? Or do I have to bite the bullet and have the entire gear duplicated from scratch?

Any help would be greatly appreciated, including any contact information anyone might have for any machine shops that might specialize in this type of repair.

Thanks, John

It's made of pure Unobtainium, so it HAS to be repaired, or duplicated. Does anyone have any experience with repairing a broken tooth on a gear? It's a straight-cut gear vs. helical, so that might simplify things somewhat.

I don't know the exact composition of the gear, but it's a steel alloy of some sort, hardened. Can the missing tooth be built up with MIG or TIG, then machined, then hardened? Should the gear be softened prior to welding and machining, then the entire gear rehardened? Or do I have to bite the bullet and have the entire gear duplicated from scratch?

Any help would be greatly appreciated, including any contact information anyone might have for any machine shops that might specialize in this type of repair.

Thanks, John