Impulse

Silver Member

My log bucking rating is about 1/2 a notch above novice. I kick logs around, maybe teeter them on something, aim for 16" and try to keep the chain out of the dirt. I recently took down 11 trees, some maybe 75+ feet tall. Needless to say, I have a lot of cutting to do. I've got a Fiskar X27 and a mean swing so I think I'm set on the splitting, but cutting these logs down to size is hard on the ol' spinal fusion.

I think it is time I construct a sawbuck. I have been tinkering around with some designs, but I haven't really liked any of them. It seems that the designs I have seen on Google either require moving logs around or still allow the log to bind on the chain or pieces drop all over.

I was hoping I could throw my design up here, explain my thinking and you guys could tell me why my design sucks so I can get to something better.

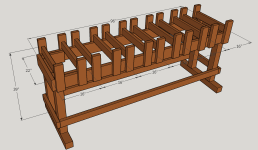

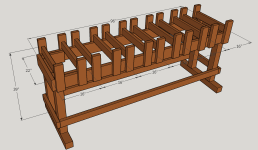

My thoughts on this are that I can use Pedro to throw a log up and I can then cut @ 16" with both ends of the cut pieces and remaining log always supported. The pieces shouldn't fall to the ground so I won't have to bend over so much. The span is supported by 2x6 lumber with 2x4s perpendicular to raise the log up so I don't cut into the frame. I considered a 3rd 2x6 in the middle, but figured it would get in the way and I'm thinking that 2 would be enough. I've got small 2x4s on end to keep anything from rolling off. I thought about notching the 2x4s to allow a log to park itself, but I don't know if that is necessary either. For the height, I really just took a guess. I'm 6'3" and the higher up while still being able to safely cut it, the better.

I would appreciate any thoughts and criticism or if you wanted to post better ideas.

Thanks

I think it is time I construct a sawbuck. I have been tinkering around with some designs, but I haven't really liked any of them. It seems that the designs I have seen on Google either require moving logs around or still allow the log to bind on the chain or pieces drop all over.

I was hoping I could throw my design up here, explain my thinking and you guys could tell me why my design sucks so I can get to something better.

My thoughts on this are that I can use Pedro to throw a log up and I can then cut @ 16" with both ends of the cut pieces and remaining log always supported. The pieces shouldn't fall to the ground so I won't have to bend over so much. The span is supported by 2x6 lumber with 2x4s perpendicular to raise the log up so I don't cut into the frame. I considered a 3rd 2x6 in the middle, but figured it would get in the way and I'm thinking that 2 would be enough. I've got small 2x4s on end to keep anything from rolling off. I thought about notching the 2x4s to allow a log to park itself, but I don't know if that is necessary either. For the height, I really just took a guess. I'm 6'3" and the higher up while still being able to safely cut it, the better.

I would appreciate any thoughts and criticism or if you wanted to post better ideas.

Thanks