J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,928

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

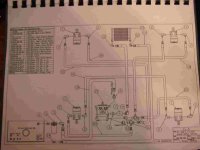

I need some one that has a hydraulic schematic to check and see if the tram pump used in the PT's is a closed loop system. In a closed loop system, the oil is circulated from the pump through the wheel motors, and back to the pump. The charge circuit makes up for any losses in the system. We may have a modified circuit is our PT's. What this is leading to is that any foreign particles induced into the system goes directly to tank and only some of that oil is filtered. The PTO is sucking oil directly from the tank, and so is the steering and lift pump. The tram pump and wheel motors is always filtered, and therefore less prone to wear. There seems to be no reason why , if we have the space, to install input filters in all the circuits. I would estimate the cost to be about $50.00 to filter each circuit. On my 1445, the replacement cost for the steering pump is about $95.00, PTO pump, about $350.00, and the tram pump about $2200.00.

I have replaced both the steering and the PTO pump. The technician that looked at them said it was due to wear. In my opinion, this was caused by partially filtered oil. I don't know if any one could determine how long it would take the tram pump to filter 20 gal of oil, because at the same time, the PTO and lift pumps are recirculating partially filtered oil continuously. I don't feel that this is the best method that could have been used. What say you?

I have replaced both the steering and the PTO pump. The technician that looked at them said it was due to wear. In my opinion, this was caused by partially filtered oil. I don't know if any one could determine how long it would take the tram pump to filter 20 gal of oil, because at the same time, the PTO and lift pumps are recirculating partially filtered oil continuously. I don't feel that this is the best method that could have been used. What say you?