Thanks for the helpful suggestions! I'll probably buy the tool on E-Bay (only thing is he wants half the price of the tool for the shipping, in addition to the tool price).

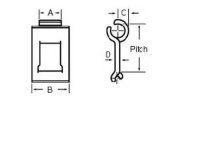

These links don't have pins and side-links like roller chains have. Each link is one square piece with one side a cylindrical housing of sorts with a slot and the other side a flat side with a rounded edge made onto it for wear. Then each side of the link is just a flat leg. Each link is identical and made in one piece.

They're so hard and springy I can't get my vise tight enough to hold for as hard as I have to hit to drive the rounded edge down into the slot. I can remember doing this many years ago to shorten a worn chain, but I don't remember ever tackling a new one that won't slide down into the slot.

And even if I master this part of it, (I'm trying to make two chains of 38 links each from a new 100 link piece), I must wrap each around the drill sprockets first before reconnecting the two links of each new chain, so this must be done on the grain drill and not at my vise!

I'm really staring to look more and more over at my blow torch !!!!:confused2: