Loren49

Veteran Member

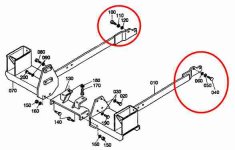

On a recent visit to my brother we noticed a loose bolt on the loader mount. On closer inspection we found it was very close to becoming a major problem (damage wise and possible injury) There were 3 missing bolts and 8 were sheared off. Not much left holding. We were able to make the repair (lots of hours getting old bolts out and actually did a little modification. The tractor is a 30 hp 4wd - no need to mention make - don't need a fight. (not a Kioti) I will say that when I returned home I checked and torqued my mount and all was fine. Just a reminder that may save someone a problem. Check for loose bolts.

Loren

Loren