You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Laying Pipe

- Thread starter WVBill

- Start date

/ Laying Pipe

#1

tdenny

Platinum Member

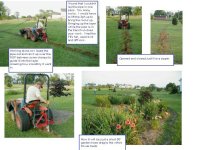

Re: Laying Pipe part 2

Nice place you've got there WVBill. So all of that poly pipe you put in was for watering the outlying areas? I am going to need to do something of that nature eventually. Are you just hooking up outdoor spigots to the ends of those pipes?

I'm not much of a plumber so I get easily confused while working with water.

Nice place you've got there WVBill. So all of that poly pipe you put in was for watering the outlying areas? I am going to need to do something of that nature eventually. Are you just hooking up outdoor spigots to the ends of those pipes?

I'm not much of a plumber so I get easily confused while working with water.

RonL

Banned

- Joined

- Dec 22, 2001

- Messages

- 430

- Location

- Worcester, Massachusetts

- Tractor

- Caterpillar 416C IT, Caterpillar D3G, previously owned a Ford 1910

WVBILL

Generally, I don't like to use mechanical implements when laying pipe. I do , however, sometimes have dinner at a fine restaurant and have a bottle of wine.

Sorry, I couldn't help myself.

RonL

Generally, I don't like to use mechanical implements when laying pipe. I do , however, sometimes have dinner at a fine restaurant and have a bottle of wine.

Sorry, I couldn't help myself.

RonL

Alan L.

Elite Member

Re: Laying Pipe part 2

Nice job. I have a similar project to do. What type of plumbing fittings did you use to hook the poly pipe to the outdoor faucets? How deep is the pipe?

I want to just have those frost free faucets coming out of the ground at various intervals. Looks like a subsoiler might do the same thing as the rig you have there.

Nice job. I have a similar project to do. What type of plumbing fittings did you use to hook the poly pipe to the outdoor faucets? How deep is the pipe?

I want to just have those frost free faucets coming out of the ground at various intervals. Looks like a subsoiler might do the same thing as the rig you have there.

WVBill

Veteran Member

Re: Laying Pipe part 2

I haven't finished plumbing yet but I bought 3/4" barb - to - 1/2" fpt "el" fittings that I'll put at the end of the run. Then a 24" piece of 1/2" galvanized pipe will rise out of the ground with a faucet on top. I'll sink a 4' green fence "T" post into the ground right next to the 1/2" pipe riser for support.

I suppose I could skip the galvanized risers and just run the black poly up the support but 1) I wasn't sure about the UV resistance of black poly and 2) I didn't want to have to worry about hitting it with the weed whacker blade.

The poly pipe is only about 8" deep - doesn't run under any vehicle traffic areas. I'll blow it out with compressed air each fall.

On the supply end I'll add a npt - to - hose converter to the current outside sill cock and use a courrigated copper pipe to connect to the galvinized riser pipe. This way, I'm not altering the house's plumbing so no permits/inspections/etc. are required.

I haven't finished plumbing yet but I bought 3/4" barb - to - 1/2" fpt "el" fittings that I'll put at the end of the run. Then a 24" piece of 1/2" galvanized pipe will rise out of the ground with a faucet on top. I'll sink a 4' green fence "T" post into the ground right next to the 1/2" pipe riser for support.

I suppose I could skip the galvanized risers and just run the black poly up the support but 1) I wasn't sure about the UV resistance of black poly and 2) I didn't want to have to worry about hitting it with the weed whacker blade.

The poly pipe is only about 8" deep - doesn't run under any vehicle traffic areas. I'll blow it out with compressed air each fall.

On the supply end I'll add a npt - to - hose converter to the current outside sill cock and use a courrigated copper pipe to connect to the galvinized riser pipe. This way, I'm not altering the house's plumbing so no permits/inspections/etc. are required.

tdenny

Platinum Member

Re: Laying Pipe part 2

WVBill,

<font color=blue>On the supply end I'll add a npt - to - hose converter to the current outside sill cock and use a courrigated copper pipe to connect to the galvinized riser pipe. This way, I'm not altering the house's plumbing so no permits/inspections/etc. are required.

</font color=blue>

Could you explain this a little more. Sorry for my ignorance. That is exactly what I'm looking to do (I think).

WVBill,

<font color=blue>On the supply end I'll add a npt - to - hose converter to the current outside sill cock and use a courrigated copper pipe to connect to the galvinized riser pipe. This way, I'm not altering the house's plumbing so no permits/inspections/etc. are required.

</font color=blue>

Could you explain this a little more. Sorry for my ignorance. That is exactly what I'm looking to do (I think).

njrqs

Veteran Member

Re: Laying Pipe part 2

Bill

They are a great tool hey !!

I can only use mine when the ground is soft, and have to cut the trench first like you say, then go back and lay the pipe in another pass.

I laid 400' of 1" pipe no worries.

My pipe layer has a much larger diameter pipe than yours and is supposed to lay up to 1 1/2" pipe.

Well the other day I tried to lay 1 1/4" pipe and it kinked all the time.

It was a cold day and I didn't have a ROPS or a helper so couldn't get the pipe nice and high like yours but I was dissappointed none-the -less.

I doubt if I could do 1 1/2" - It is way too rigid for the layer I think.

Cheers

Bill

They are a great tool hey !!

I can only use mine when the ground is soft, and have to cut the trench first like you say, then go back and lay the pipe in another pass.

I laid 400' of 1" pipe no worries.

My pipe layer has a much larger diameter pipe than yours and is supposed to lay up to 1 1/2" pipe.

Well the other day I tried to lay 1 1/4" pipe and it kinked all the time.

It was a cold day and I didn't have a ROPS or a helper so couldn't get the pipe nice and high like yours but I was dissappointed none-the -less.

I doubt if I could do 1 1/2" - It is way too rigid for the layer I think.

Cheers

emery

Silver Member

Just a compliment on such a nice place and such great photos with text... First class!

WVBill

Veteran Member

Re: Laying Pipe part 2

tdenny: I used this set up on the other side of the house. I'll take a picture tonight and post it with explanation.

Niel: It was 90 degrees F the day I laid my pipe and I set it out in the sun early in the day so it was good and warm. Funny thing: it was crimped on both ends of the 400 foot roll at the factory and when I went to cut it just prior to laying it the air pressure had built up from the heat of the day and as I sliced into the pipe the air release was quite a surprise!

Even on a hot day, I don't think 1 1/2" pipe would be flexible enough to make it through the bend of a pipe layer tool like ours.

emery - thanks.

tdenny: I used this set up on the other side of the house. I'll take a picture tonight and post it with explanation.

Niel: It was 90 degrees F the day I laid my pipe and I set it out in the sun early in the day so it was good and warm. Funny thing: it was crimped on both ends of the 400 foot roll at the factory and when I went to cut it just prior to laying it the air pressure had built up from the heat of the day and as I sliced into the pipe the air release was quite a surprise!

Even on a hot day, I don't think 1 1/2" pipe would be flexible enough to make it through the bend of a pipe layer tool like ours.

emery - thanks.