raykos

Silver Member

Hi all,

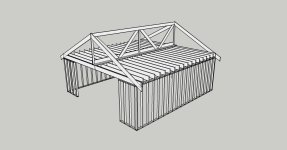

My house was built with an attached 24'x24' garage, which I turned into a family room. Now, I'd like to build a seperate 24'x24' garage for my JD2305 and implements, and use the same technique for the roof as the original attached garage had. What makes this building method so appealing is there is no centrer load bearing wall; the garage is all open space. I've included rough SketchUp jpg to hopefully show what I mean.

The only thing I've been able to find is that it's a ridge board framed roof; but haven't been able to find anything about the 'W' type of truss underneath the ridge board? Can anybody lead me to more information about this type of roof construction with the 'W' truss? I'd like to duplicate this method and not use trusses.

There's been a lot of discussions about pole garages and barns vs. tradional stick building/framing; but, one of the things I couldn't find(maybe just didn't use the right search words) deals with insulating the pole type structures. It seems that in order to insulate a pole structure, you have to have tradional 16" or 24" OC framing inside, in order to hold the insulation and any wall material? So why not just build a frame structure to begin with?

If I could put up a pole type structure it would probably be easier, but then there's the issue of insulating; would I be building a frame structure anyhow?

My house was built with an attached 24'x24' garage, which I turned into a family room. Now, I'd like to build a seperate 24'x24' garage for my JD2305 and implements, and use the same technique for the roof as the original attached garage had. What makes this building method so appealing is there is no centrer load bearing wall; the garage is all open space. I've included rough SketchUp jpg to hopefully show what I mean.

The only thing I've been able to find is that it's a ridge board framed roof; but haven't been able to find anything about the 'W' type of truss underneath the ridge board? Can anybody lead me to more information about this type of roof construction with the 'W' truss? I'd like to duplicate this method and not use trusses.

There's been a lot of discussions about pole garages and barns vs. tradional stick building/framing; but, one of the things I couldn't find(maybe just didn't use the right search words) deals with insulating the pole type structures. It seems that in order to insulate a pole structure, you have to have tradional 16" or 24" OC framing inside, in order to hold the insulation and any wall material? So why not just build a frame structure to begin with?

If I could put up a pole type structure it would probably be easier, but then there's the issue of insulating; would I be building a frame structure anyhow?