Scotty370

Platinum Member

- Joined

- Dec 18, 2008

- Messages

- 898

- Location

- Buffalo, New York

- Tractor

- 318 John Deere, 4200 John Deere, 1947 John Deere "M"

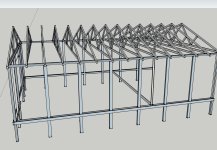

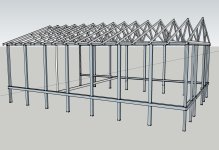

I'm in the process of a Google-Sketch-up design for a Pole Barn/Shed. I borrowed some design from KennyD, and others. This is a work in progress, so I'm looking for commentary. I know I'll get comments on "Taller Door, Higher ceiling etc." but what I'm looking for is structual comments. Am I over building this? All wood will be rough-cut full 2"x4", or 2"x6" Hemlock. Side wall 'poles' will be two-2"x6" laminated together. I'd thought of shrink wrapping the bottom 4' with something like boat winter wrap. The posts will go 48" into the ground. The trusses will be made from 2x4 rc hemlock. The size is 30'x42'. The post are on 6'centers and the trusses, 3' centers. The skirt board on the outside is a 2x6, and the one inside will be a 2x4 for flooring slab in the front. the rear will be open with a gravel floor for implement storage undercover. A parting wall will be installed. The roofing and siding will be steel. I havn't yet drawn the roof purlins and wall girts. Comments please. ~Scotty