RayCo

Veteran Member

- Joined

- Jul 24, 2005

- Messages

- 1,029

- Location

- Chester County, PA

- Tractor

- Kubota BX24, Case 580 Super L

I'm not aware of any forums elsewhere on the WWW that are more geared toward this, so please feel free to direct me somewhere more appropriate if this is too off-topic.

I've lately found the need to construct a few things around the house. My four year old daughter now has a little tractor and a Gator, so it is time that she have her own equipment shed. So, I'm building her one. I've also found that the gazebo I have is damaged beyond repair, and I need to build a new one. Also on the list is a snack stand for the wildlife in my area. So, these requirements have led me to have these two questions:

Is there an alternative to using pressure-treated wood in some situations. For instance, for the wildlife snack stand, the whole structure will be exposed to the elements, so my natural inclination is to use all pressure treated wood. But, if there is an option of using normal lumber and chemically treating it myself, at least for the wood that will not be in direct contact with the ground, I am not aware of it. I also have at least somewhat of a concern about exposing the animals to arsenic.

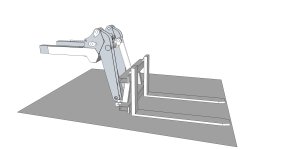

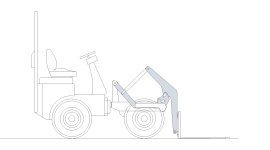

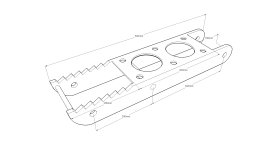

Can anyone recommend 3D modeling software that is reasonable for a hobbyist who'd just like to virtually assemble some 2x4s and plywood before turning on the saw? I've found that Pro/Engineer is a bit overkill in its price and learning curve. Google Sketchup drives me insane. I'm currently playing around with a product called DesignWorkshop Lite. It seems okay, but I'm looking for something that'd be more geared toward building wooden structures and has tools specific to working with lumber, not just any abstract 3D shape.

Thanks for anything.

I've lately found the need to construct a few things around the house. My four year old daughter now has a little tractor and a Gator, so it is time that she have her own equipment shed. So, I'm building her one. I've also found that the gazebo I have is damaged beyond repair, and I need to build a new one. Also on the list is a snack stand for the wildlife in my area. So, these requirements have led me to have these two questions:

Is there an alternative to using pressure-treated wood in some situations. For instance, for the wildlife snack stand, the whole structure will be exposed to the elements, so my natural inclination is to use all pressure treated wood. But, if there is an option of using normal lumber and chemically treating it myself, at least for the wood that will not be in direct contact with the ground, I am not aware of it. I also have at least somewhat of a concern about exposing the animals to arsenic.

Can anyone recommend 3D modeling software that is reasonable for a hobbyist who'd just like to virtually assemble some 2x4s and plywood before turning on the saw? I've found that Pro/Engineer is a bit overkill in its price and learning curve. Google Sketchup drives me insane. I'm currently playing around with a product called DesignWorkshop Lite. It seems okay, but I'm looking for something that'd be more geared toward building wooden structures and has tools specific to working with lumber, not just any abstract 3D shape.

Thanks for anything.