tkappeler

Platinum Member

I've never seen that small of a pump truck before.

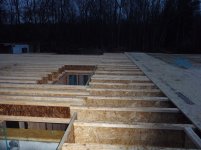

I see you used engineered wood beams. Were they significantly cheaper than steel? Around here steel beams are common.

I do not have a line item price breakdown for the beams nor a new vs surplus cost for the steel, so it's hard to say. There are some steel places around here where you could get surplus I beams at a significant savings. The architect specified these as the loads did not warrant steel and he was being cost effective, so I am guessing the steel would have been more.