hawkeye08

Elite Member

I would avoid the plastic multipart manifolds if at all possible. I worked for a hotel with Manablock sectional valves (much like Viega MANABLOC Water Distribution System, Central Manifold System) and it was leaking between sections to the point where the threaded rods had to be re-tightened in ~3 years and several had to be replaced in 5-6 years.

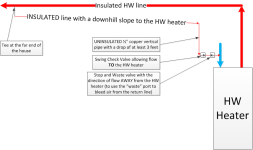

Personally, if I ever redo my house, I will run a 3/4" trunk and tee off of it with 1/2" pex. Then I will re-setup a thermosiphon to keep hot water circulating along the truck. My problem with home runs is that they mean that I would need to run all the water in the line out to get hot water, so 60' of 1/2" pex vs 10' of 1/2" pex

Aaron Z

If this turns out to be a problem, they sell little pumps that sit at the end (near faucet). When you want hot water, you press a button for the pump and it pumps the hot side into the cold side until hot gets there.