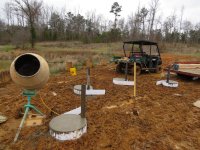

Nice touch with the cedar logs. Are they from your land? I use them on porches and gazebo's at my place. I found that when I put them in the ground, they start to rot fairly quickly. I have two on my porch that I did that way and I noticed the rot in about five years. They will be coming out this year and I will put them on to of a concrete pad. All of mine rest on concrete several inches above the ground. I drill a 3ft deep, 1ft wide hole in the ground and put a five foot length of channel iron in the hole. Then I fill the hole with concrete and make a form out of wood or a few inches cut off of a sono tube to get above grade. Then I put the post on top of the concrete and drill two holes through it and the c channel. Since the logs are so thick, I use galvanized threaded rod to bole it all together. This has proven to be a good long term solution to the rotting log problem.

Eddie