quicksandfarmer

Veteran Member

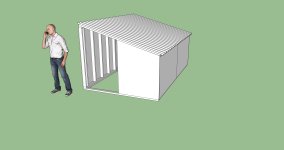

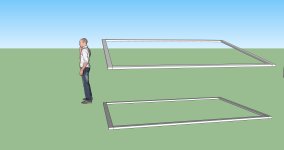

So I'm getting ready to build some shelters for goats. I need them to be movable, although I tend not to move them very often. I have a few now that were designed to be moved by a tractor and they're a pain to move, so I'm thinking it might be better to have a design that I can take apart to move. I figure if I can break it into pieces that two people can carry and will fit on a wagon or the back of a pickup truck that will be easier than trying to move the whole thing assembled. It will also allow me greater freedom in where I put it.

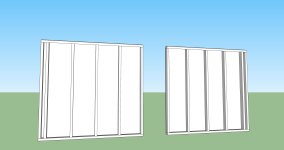

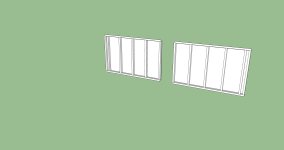

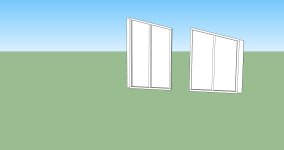

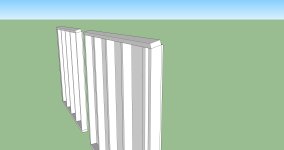

So I'm looking for ideas on how to construct it. I'm thinking a shelter with a size somewhere between 8'x8' and 8'x12', tall enough for a person to go into. For the roof I have some used pieces of heavy 8' galvanized corrugated sheet metal, it can span its length without rafters which simplifies things. I would attach it at each end with screws, then I could just unscrew it to disassemble the roof. For the walls I'm thinking 2x4 framing sheathed in either plywood or corrugated metal. I figure if each wall is under about 150 lbs then two people can move it. If I can't do that then I'll have to figure out a way to break the walls into sections. The question is how to connect the walls together at the corners, to have a reasonably strong connection that goes together and comes apart easily. I'm thinking of using a Simpson Strong-Tie corner brace, something like this one:

ML | Deck Connectors | Decks | Decks and Fences | Wood Construction Connectors | Connectors | Simpson Strong-Tie

I figure if I put it in with screws I can take the whole thing apart and put it back together again with a screw-gun.

I'd appreciate any thoughts anyone has. This isn't going to be fine carpentry, it's just to keep the wind and rain off of the goats. I would like it to be reasonably durable though.

Thanks.

So I'm looking for ideas on how to construct it. I'm thinking a shelter with a size somewhere between 8'x8' and 8'x12', tall enough for a person to go into. For the roof I have some used pieces of heavy 8' galvanized corrugated sheet metal, it can span its length without rafters which simplifies things. I would attach it at each end with screws, then I could just unscrew it to disassemble the roof. For the walls I'm thinking 2x4 framing sheathed in either plywood or corrugated metal. I figure if each wall is under about 150 lbs then two people can move it. If I can't do that then I'll have to figure out a way to break the walls into sections. The question is how to connect the walls together at the corners, to have a reasonably strong connection that goes together and comes apart easily. I'm thinking of using a Simpson Strong-Tie corner brace, something like this one:

ML | Deck Connectors | Decks | Decks and Fences | Wood Construction Connectors | Connectors | Simpson Strong-Tie

I figure if I put it in with screws I can take the whole thing apart and put it back together again with a screw-gun.

I'd appreciate any thoughts anyone has. This isn't going to be fine carpentry, it's just to keep the wind and rain off of the goats. I would like it to be reasonably durable though.

Thanks.