Milo

Platinum Member

- Joined

- Aug 7, 2006

- Messages

- 939

- Location

- Preston County, WV

- Tractor

- JD 3520, Ferris Z2100, Kawasaki Mule Pro MX, Honda Pioneer 520

Just in the planning stage for constructing a free standing multi-use, climate controlled, building to house motorcycles, tool benches, gun safe, a couple of exercise machines, storage, etc. probably around 24x36. I'm thinking a 12'x 24' carport on the end would make a good place to park the rotary cutter, rear blade, FEL with easy access from the 24' side.

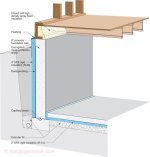

So far I've decided on footers and block which will be insulated and the concrete floor poured to that, with at least one 4" (or 6") block exposed above the slab and framed walls resting on that. That rim of block will be directly exposed to the outside and radiate cold right in so it'll have to be covered. My thought was to have the 2x4(or 6") wall flush with the blocks on the inside, filling the wall cavity with fiberglass, covering the inside studs straight down to the floor with foam board such as 1" T&G blue board, then drywall. Am I on the right track here or is there a better way? Any problem with rigid foam board under drywall? It'll be kept heated or cooled all year so I want it very well insulated. Exterior will be Hard-plank to match the house.

So far I've decided on footers and block which will be insulated and the concrete floor poured to that, with at least one 4" (or 6") block exposed above the slab and framed walls resting on that. That rim of block will be directly exposed to the outside and radiate cold right in so it'll have to be covered. My thought was to have the 2x4(or 6") wall flush with the blocks on the inside, filling the wall cavity with fiberglass, covering the inside studs straight down to the floor with foam board such as 1" T&G blue board, then drywall. Am I on the right track here or is there a better way? Any problem with rigid foam board under drywall? It'll be kept heated or cooled all year so I want it very well insulated. Exterior will be Hard-plank to match the house.