khd

Gold Member

I decided I needed a small building for the tractor...I know, I know....go big or its full before its built...anyway I capitalized on the boss's okay for a "shed" and always being a traditionalist I went for a smaller building and sunk the money in astetics. Because the job limits the time I have for such things , I designed the building and got with the Amish in OH to cut it.

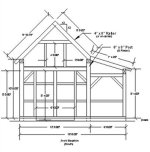

It is basically a 12 x 16 main building (Sobon style) with a 6' clear span, open lean-to. 10' sidwalls, 12/12 roof and half loft all cut from green white oak. I also had them do the siding, shiplapped,rough sawn hemlock and 4/4 oak for the loft flooring. I am attaching a couple of renderings of the design. The people I had cut it specialize in large frames in the traditional utilitarian style and when I went to see their work, I was very impressed.

The design started last May and I finally commited to the job in July. I'll be posting quickly to bring the story to present.

Regards,

Kevin

It is basically a 12 x 16 main building (Sobon style) with a 6' clear span, open lean-to. 10' sidwalls, 12/12 roof and half loft all cut from green white oak. I also had them do the siding, shiplapped,rough sawn hemlock and 4/4 oak for the loft flooring. I am attaching a couple of renderings of the design. The people I had cut it specialize in large frames in the traditional utilitarian style and when I went to see their work, I was very impressed.

The design started last May and I finally commited to the job in July. I'll be posting quickly to bring the story to present.

Regards,

Kevin