Victory! Just ran the machine for a couple hours with zero issues. Pulled a couple stumps, then hauled off the wood and graded back over with the loader bucket. Not a hiccup the whole time. I only had this set up in a temporary fashion at the moment to see if it would work. I happened to have a PWM DC motor controller with programmable soft start laying around the electronics bench. This particular model soft starts as soon as it powers on. Perfect for use with the signal from the shuttle shift stalk. Also can be set to display either voltage or amperage in use. Also nice.

I took the plugs from the original controller so it could plug straight into the harness. I set it up with a ganged ground to both solenoids, and the positive from the controller going to a 3-position toggle switch. That way I could set the toggle switch for sending power to either the forward or reverse solenoid, then engage the shuttle shift to forward to activate the solenoid and engage the selected clutch. I settled at a 2.5s soft start engagement time, that worked pretty good. I just ordered another controller, so in the permanent installation I'll have one controller for forward and one for reverse, that way the toggle switch will be eliminated and the shuttle will work just like it originally did. These will tuck up under the dash just like the original. They're rated for way more power than needed in this application so I'm hoping they'll be pretty hardy.

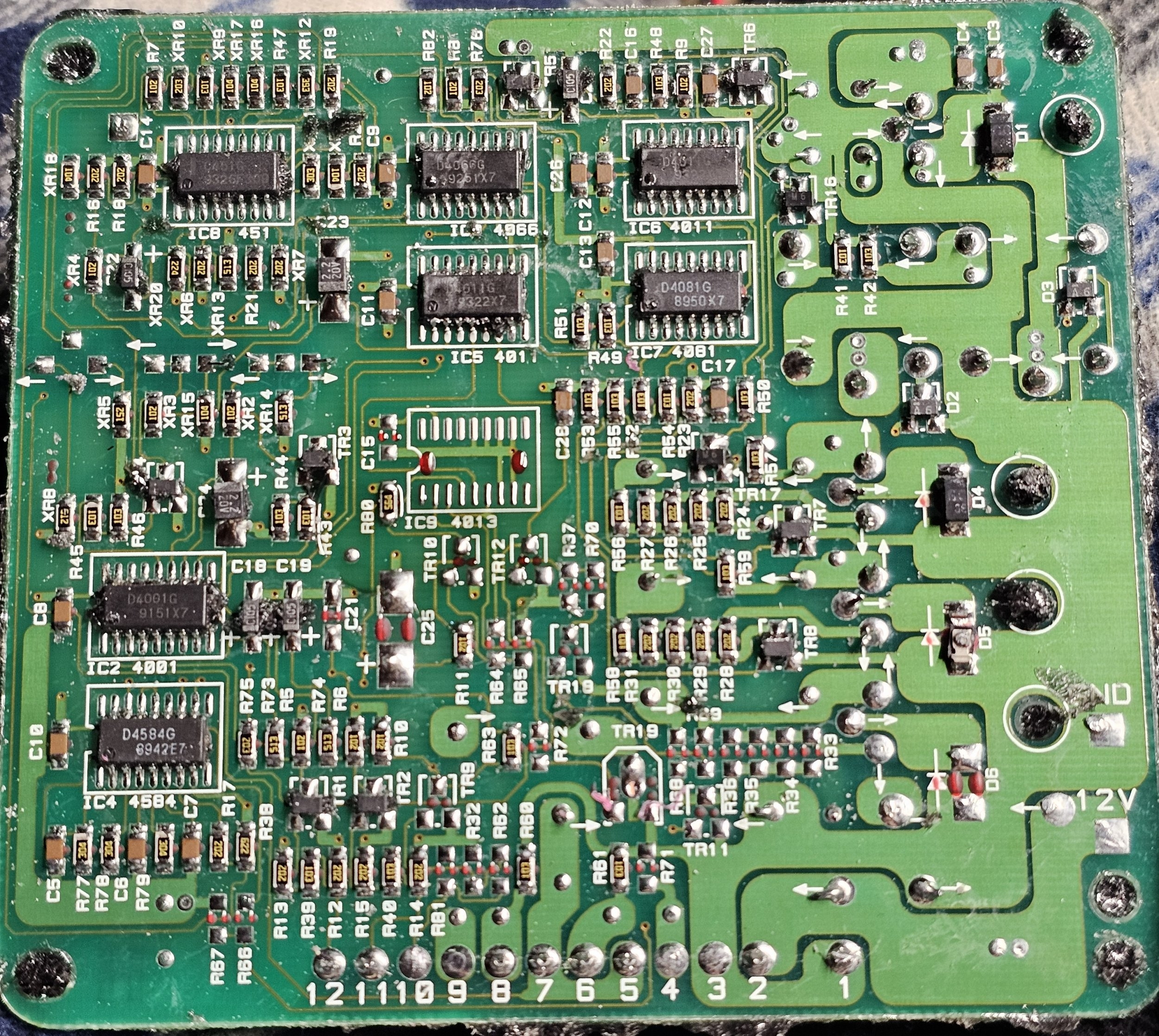

Speaking of which, the original control module is unavailable anywhere as far as I can tell. These DC motor controllers are available on eBay for around $25-$30 each. I'll probably order some spares.

View attachment 837648