rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 8,291

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

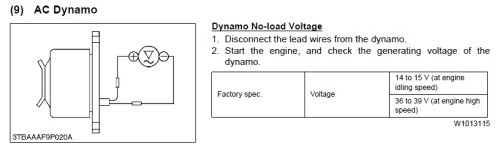

Thanks for the information. I don稚 have any need to upgrade right now. I just want it to charge the battery. I wonder if I might have a bad wire. From what I致e read tonight the dynamos rarely go bad. They are pretty simple in construction. Any idea what voltage should I expect to get off the dynamo when I test it?

Yes, they rarely go bad.

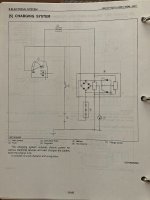

An electrical system for those old tractors is very simple. I'll go through the parts one by one with you over the next few days if you like.

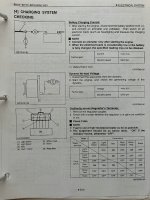

BTW, from the symptoms you have mentioned so far I would say there is a good bet your problem is a bad Voltage Regulator - it is what Cabin Dweller is calling the IC regulator, because some new voltage regulators have Integrated Circuits insteas of solenoids. Which ever type it is - either IC or solenoid type, voltage regulators not only regulate voltage, but they also prevent the battery from slowly discharging back through the generator coils overnight. You can check that several ways, but the simplest is by charging up your battery as usual in the evening... and then when you put it back in the tractor DO NOT hook up both leads to the battery. Check battery voltage in the morning and it should be what it was the night before. Hook it up and the battery will start the tractor fine.

Next afternoon, charge up the battery and do the same tests but this time hook up the battery as normal and let it all set that way overnight. If the battery is flat the next morning, it is most probable you have a bad Voltage Regulator. They do wear out. Replace it with whatever type you have in there now. In the aftermarket sometimes the old-fashioned solenoid type are better than the inexpensive IC device type. Butif you can get OEM you may be able to use either one.

OK... Onwards to the way a basic electrical circuit works in our little tractors.

1. It always starts with some kind of a device that rotates coils & magnets past each other, because that creates Alternating Current. The magnets and coils are wound and spaced to that in the diesel's 1000 to 3000 rpm range it device will put out 12 to 20 volts.

Usually the device itself looks like a can with a pulley on one end and is spun by a fan belt. In middle USA speak, it is either a "generator" (what you are calling a dynamo) or "alternator" depending on if the coils are rotating or the magnets are rotating. Either one will work for you. They are very reliable and easily rebuilt.

There are two wires coming from this device. You don't need to disconnect them, just clip your digital voltmeter across the two wires, start the motor, and see what you get. More rpm will equal more volts. Expect to see 12 to 20 volts and note if it is AC or DC on the meter.

This voltmeter test coupled with the overnight test described above is going to tell us where to look next.

2. BTW, it seems an aside, but before we trip over terminology we ought to get on the same page about whether you have a generator or an alternator - not that it matters to the tractor. It can use either. It's confusing because in most English speaking countries "dynamo" refers to a combination of a motor driving an electrical generator. Therefor a Honda generator is actually a a dynamo. So is the Generac many rural houses have to supply power during power failures. The gas or diesel powered welding machine in the back of the portable welder's pickup truck is a dynamo. It's a combination of motor and electrical generator. But it doesn't matter to the truck.

3. Next time: How the AC voltage made in the generator or alternator becomes a usable DC voltage which is then regulated in the Voltage regulator....

rScotty