Kubota Tee

Gold Member

- Joined

- Dec 14, 2009

- Messages

- 280

- Location

- Hudsonville, MI

- Tractor

- Kubota L5740 HSTC-3, Kubota L3540HST-3 (sold)

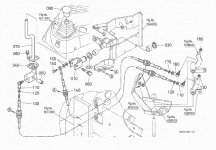

A bit of background . . . I purchased my 2012 Grand L5740HSTC with 250 hrs in 2017. Now it has 450 hours. 6 weeks ago, the cable that connects the FEL joystick to the up/down hydraulic valve broke rendering the FEL unusable. The second cable that controls the curl function was still working. Once I confirmed that the valve was still functional (manually tested it), I went about disconnecting the cable and ordered up a new one. The replacement was fairly straightforward - see parts diagram for depiction of this cable.

Now . . just yesterday, the screw that connects the cable to the joystick (part 110 in the exploded view diagram) snapped off inside the bottom of the joystick again rendering the FEL up/down unusable. I was fortunate to get the broken piece out and have ordered a new one. See pic of the broken piece.

So - here is my question. Are these FEL cable issues due to improper adjustment of the cable itself? Poor Joystick usage? Something completely different? As I go to reassemble this again, is there any advice on how to properly adjust this cable for the best operation of the FEL and longevity of the cable/connections?

Now . . just yesterday, the screw that connects the cable to the joystick (part 110 in the exploded view diagram) snapped off inside the bottom of the joystick again rendering the FEL up/down unusable. I was fortunate to get the broken piece out and have ordered a new one. See pic of the broken piece.

So - here is my question. Are these FEL cable issues due to improper adjustment of the cable itself? Poor Joystick usage? Something completely different? As I go to reassemble this again, is there any advice on how to properly adjust this cable for the best operation of the FEL and longevity of the cable/connections?