eCRX

Bronze Member

- Joined

- May 25, 2016

- Messages

- 74

- Location

- Ayr

- Tractor

- 2004 Massey Ferguson GC2300, 2015 Cub Cadet XT2

I'm building a power rake and don't have much welding experience. I'm maxing out my fabrication skills to be perfectly honest and most of the reason for building my own power rake is to learn how to weld.

www.tractorbynet.com

www.tractorbynet.com

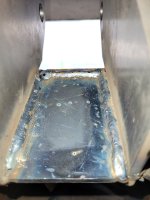

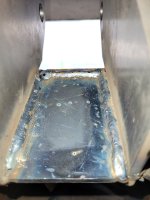

Would appreciate some feedback on my welds. Mostly just want to know which weld looks the best, and which one looks the worst, and why - so i can use it as my reference. I'm saving the most critical part for last... I need to weld 80+ (AR400 1/4") teeth to the SCH40 drum so I'm hoping to be good enough by the time I get to that stage.

Thanks in advance!!

Power Rake Build - 54"

I started designing\modeling a power rake over the winter. (Got frustrated with sketchup so I purchased a student version of solidworks.) A couple weeks ago I started the build. It will be used by a GC2300 (22.5hp) and my brother-in-laws 26hp (L2650?) Kubota some info: 54" x 6" sch40 main...

Would appreciate some feedback on my welds. Mostly just want to know which weld looks the best, and which one looks the worst, and why - so i can use it as my reference. I'm saving the most critical part for last... I need to weld 80+ (AR400 1/4") teeth to the SCH40 drum so I'm hoping to be good enough by the time I get to that stage.

Thanks in advance!!