You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to measure hydraulic pressure?

- Thread starter markedenfield

- Start date

/ How to measure hydraulic pressure?

#21

kenhar

Bronze Member

- Joined

- Feb 7, 2014

- Messages

- 51

- Location

- romance, ar

- Tractor

- 6640 ford, 1135 massey, 1610d yanmar, 1957 350 international utility

I would change the hydraulic filter before I did anything else. Best to eliminate simple fixes before getting into the unknown.

SPYDERLK

Super Star Member

- Joined

- Feb 28, 2006

- Messages

- 10,159

- Location

- VA

- Tractor

- JD2010, Kubota3450,2550, Mahindra 7520 w FEL w Skid Steer QC w/Tilt Tatch, & BH, BX1500

No. Pretty much the same Force fast or slow. A FULLY warmed system may lose some force/pressure at idle because internal system leakage of the hot thin fluid will cut into the low flow available - thus limiting the ability to build pressure and therefore force. Any system pumping enough to overcome internal leakage at the relief valve setpoint will lift the same. The lift will just be slower than at faster pump speeds.Are you trying to lift at idle speed? You will need to have engine running half throttle or more to get good lift force. Higher rpm gives more hydraulic force.

kennyd

Advertiser

Incorrect. RPM is related to GPM, so increasing the throttle will affect speed.Higher rpm gives more hydraulic force.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 8,258

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Higher rpm mostly moves more fluid and makes the lift happen faster. But some of you have probably noticed that raising the RPM also produces a little more force - just enough to be noticable.Are you trying to lift at idle speed? You will need to have engine running half throttle or more to get good lift force. Higher rpm gives more hydraulic force.

Here's why:

The reason for the higher force is also the reason that oil is able to lubricate small clearances between moving parts. The trick is that oil builds up a fluid wedge in front of a moving clearance between two surfaces. This moving surface clearance can be between a piston and cylinder wall, a crank and main bearings - or in the case of a hydraulic pump it is between the rotor edge and the rotor case.

The thin edge of that fluid wedge reduces friction by holding the rubbing surfaces apart. And the thick end of that wedge provides the sealing that keeps internal pressures - and the wedge itself - in place.

If the viscosity of the fluid is right, then what happens is that the sealing by the fluid wedge gets better the faster that surfaces move past each other. A better seal holds more pressure, and that extra pressure is what gives you the extra force as RPM increases.

So what you get is slightly greater force as well as much greater flow when you raise the RPMs.

All thanks to my fluid professor years ago.

rScotty

MHarryE

Elite Member

- Joined

- Feb 15, 2009

- Messages

- 2,946

- Location

- Northeastern Minnesota

- Tractor

- Kubota M7-171, M5-111, SVL75-2, RTV900XT & GR2120; CaseIH 1680 combine

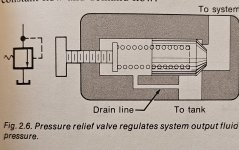

Pressure should be checked at high idle. SCUTs and CUTs in every case I know use direct acting relief valves. That means oil is working against a poppet held by a spring. Increasing flow by increasing engine speed means more flow has to go through the poppet at relief, so the open area needs to increase, and that happens by compressing the spring holding the poppet shut. Factory spec is at high idle warm oil. The shim kit adds a shim to the end of the poppet spring giving it additional pre-compression. Here is an illustration of a direct acting relief. If the pressure needs to be adjusted, this illustration shows a screw adjust but most CUTs require shimming the spring.