EdGooding

Silver Member

- Joined

- Sep 12, 2016

- Messages

- 205

- Location

- Montpelier, VA

- Tractor

- 2006 Massey-Ferguson MF-1533, 1973 Ford 3000, 1952 Ford 8N

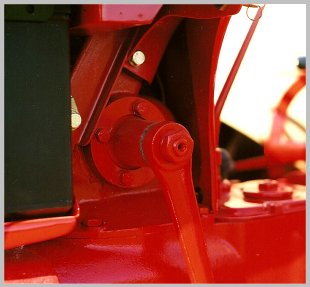

What year is your 8N or which steering gear box you are rebuilding? The 8N had two, the later one was the better one to rebuild. The pre- mid-'49 had four bolts:

The later, mid-'49 to '52 one only has two bolts:

I can show you where to install a grease zerk to help you grease it when I know which one. I definitely agree that cornhead grease is better than oil for the gear box.

The later, mid-'49 to '52 one only has two bolts:

I can show you where to install a grease zerk to help you grease it when I know which one. I definitely agree that cornhead grease is better than oil for the gear box.