sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 5,222

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

If your tractor's three point hitch has Draft ability, the hole options will usually affect the draft operation.

Your tractor's manual should tell you which hole to use for each type of work you're doing.

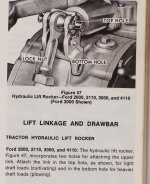

this agrees with my Ford tractors manual, in draft control mode

as an example my 3000 suggests using the top link hole for lighter implements, the lower hole for heavier units,

the 3000, 5000 mounts the top link to the rockshaft differently and IIRC the holes placements achieve the same effect - top hole lightest implement, bottom heaviest as stated above this is for draft reaction and sensitivity.

my 3000 isn't supposed to have reaction in the position control mode , but it does effect operation of the post hole digger, if the top link is placed in the top hole... it is hard to get smooth control of the up and down motion of the 3 point. if placed in the lower hole it is much smoother in operation and easier to control.... hope this makes a little sense

Last edited: