terry.dinerman

Gold Member

- Joined

- Oct 11, 2009

- Messages

- 431

- Tractor

- 1990 - JD 870

Do you think it would be possible to put a 90 degree bend in a pipe like this with a Harbor Freight bender without kinking it?

YARDGARD 10-1/2 ft. 17-Gauge Steel Top Rail for Chain-Link Fence - 328913DPT at The Home Depot

12 Ton Hydraulic Pipe Bender

The bender doesn't have a 1 3/8" die...would the 1 1/2" work?

Terry, you said you built one out of schedule 40 pipe...what diameter did you use?

I used 2"....

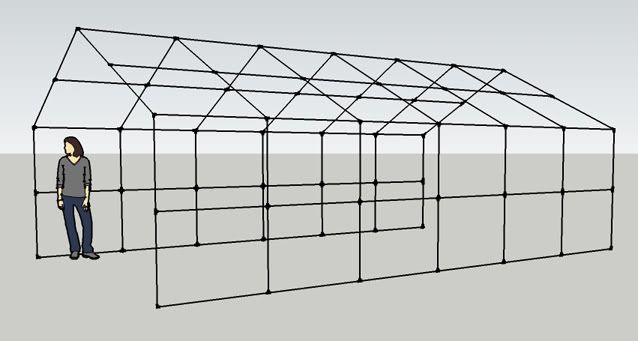

- Using batter-boards or steel layout pins, lay out and square up your structures perimeter on the ground.

- Lay out your "hoop" inside this perimeter. Lay out the center points of your eave-line bends and the peak on the ground with some stakes.

- Run a stringline around the stakes

- Spray paint the line

- Remove the string - If done right, the string will leave a clear mark in the middle of the paint swatch

- Lay the pipe down next to the long axis.

- Mark the center of each bend on the first pipe as you go. Record the measurements and repeat on each pipe.

- Center up the bending shoe on these marks on every pipe to assure consistency between hoops.

- Use additional stakes to keep the pipe on the line as you move along the pipe with the bender and bend each angle to the paint line

- Slight over-bends may be required to accommodate the spring-back from the elasticity of the pipe, so bend to the line, relax the bender, check the bend and re-bend as necessary.

The structure I built was a lean-to, so only required a single 20' join of pipe for each hoop to provide 12 foot of interior clearance and an 8 foot eaveline. Larger hoops could be bent in halves and either welded or sleeved and bolted together

If you stitch the edges of adjoining sheets together with pop rivets or small nuts and bolts every 4-6 inches, you may find your structure is quite rigid.

The lean-to used a standard 26ga sheet with a drip edge made of 26ga "J" channel and did not need any cross bracing. The pop rivets were quick and a dab of silicone made it all water-tight.

Good luck and Be Safe!

T

Last edited: