4shorts

Elite Member

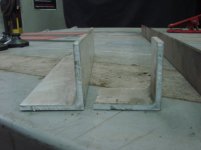

Well I had just left the shop yesterday and got in the house when I heard the pissh of an air brake so I knew it had to be the new Edwards Ironworker I ordered three weeks ago. This one is the 60 ton model. I ordered it with a set of punches, a heavy duty gauging table kit, pedestal die table,48" manual back gauge, a fabricators protractor and a 8" four way brake.

The ironworker came standard with the electric stroke control, coper/notcher and angle /plate share so It's well equipped.

Edwards fit and finish of these machines are fantastic. All good components are used such as a Leeson 5 HP motor. The Ironworker was very well packaged and everything that was ordered arrived which was a Hugh plus. After I got it all unpacked I started to install the optional items such as the 1" thick gauging table. I also ordered a couple of flexible magnetic lights from another source to put on the thing. I like lots of light. After I ran the 220 single phase power to the machine it fired right up and worked great. The last photo shows the 1/4 plate I practiced on. It did that with so little effort I could hardly believe it. Made in the USA was a big plus as well. Here's how it looks.

The ironworker came standard with the electric stroke control, coper/notcher and angle /plate share so It's well equipped.

Edwards fit and finish of these machines are fantastic. All good components are used such as a Leeson 5 HP motor. The Ironworker was very well packaged and everything that was ordered arrived which was a Hugh plus. After I got it all unpacked I started to install the optional items such as the 1" thick gauging table. I also ordered a couple of flexible magnetic lights from another source to put on the thing. I like lots of light. After I ran the 220 single phase power to the machine it fired right up and worked great. The last photo shows the 1/4 plate I practiced on. It did that with so little effort I could hardly believe it. Made in the USA was a big plus as well. Here's how it looks.