Haywire

Veteran Member

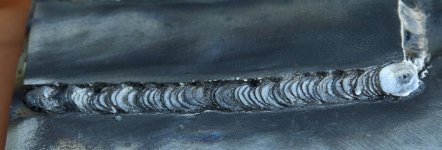

I got a bead today that finally looks like something. I was doing the little circles rather than just trying to lay a straight bead. This is Hobart 1/8" 6010 at 64 amps, electrode positive.

What can you suggest to improve on this result other than just practice? Self diagnosis tells me more consistent speed.

thanks,

Ian

What can you suggest to improve on this result other than just practice? Self diagnosis tells me more consistent speed.

thanks,

Ian