dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,037

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

So I recently got a nice upgrade to my welder with the new Miller XMT 304 and a wire feeder I picked up at an auction (separate thread). The bonus was the heavy duty welding cart that came with it. Made from 1.5" x1/8" angle and 1/8"/10ga plate shelves. It has space for 2 bottles on the back too (where the previous Thermal Arc that is for sale is sitting - anyone want it?). That will be nice as I will want to add a TIG torch to this in the near future so I will need both C25 and Ar.

So here is what I've got, and I'm looking for suggestions & comments.

Pics:

So here's my thoughts:

1. It needs hangers for the cables

2. A bank of drawers would help with storage

3. A handle on the front would help too.

4. Maybe some misc hooks and such for hanging torches and clamps

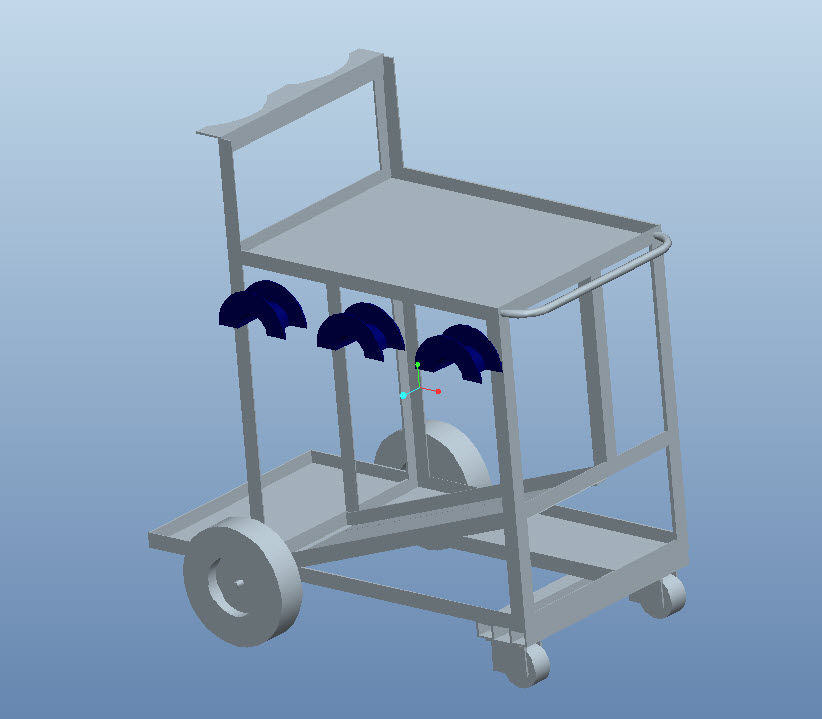

So I drew it up in CAD, just because that is what I do... and added 3 cable hangers that I made up, and a handle from 3/4" tube that sticks out about 3".

I'm thinking 2 may be better than 3 there for spacing/room. Not sure. Also not sure if 3" is enough space for the handle.

Next post...

So here is what I've got, and I'm looking for suggestions & comments.

Pics:

So here's my thoughts:

1. It needs hangers for the cables

2. A bank of drawers would help with storage

3. A handle on the front would help too.

4. Maybe some misc hooks and such for hanging torches and clamps

So I drew it up in CAD, just because that is what I do... and added 3 cable hangers that I made up, and a handle from 3/4" tube that sticks out about 3".

I'm thinking 2 may be better than 3 there for spacing/room. Not sure. Also not sure if 3" is enough space for the handle.

Next post...