Haywire

Veteran Member

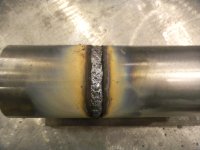

by accident... Of the 10 or so sticks I burned tonight, I had about 3 inches of bead that had the flux curl up and let loose in one piece. The rest of it wasn't anything memorable, but that's the first time I've seen 6010 flux come off on it's own when I was behind the stinger that laid it. :laughing:

Ian

Ian