jimcolt

Gold Member

There often are a questions pertaining to air plasma cutting systems with reference to comparing the performance of the low cost machines sold by importers to the more costly major brand plasma cutting systems. There are always important considerations when buying plasma cutters and welders and these considerations can be based on the needs of a particular application. Often the major need is reliability, sometimes the need is to have a wide cut quality/thickness range, and at other times the need may be based on price, or the color (brand loyalty!).

Generally speaking....all plasma cutters will cut metal....and in some cases that is enough to satisfy some hobbyist applications. The differences that you will see if you step up to the more costly (to buy.....less costly to use) major brand systems:

- Power supplies are of the latest technology. They are designed, reliability tested and built to survive in industrial environments under the rigors of production use. The primary goal of an industrial plasma power supply is to be operator friendly, reliable and to support the torch design that is used with the power supply.

-Internal circuit boards are (on some brands) are conformally coated (so shop dust does not short them) and are mounted vertically (so shop dust does not build up on them). Cooling fans operate on demand only (so less dust is pulled through the unit). There is a "clean side, dirty side" design that keeps critical components out of the fan flow area and cools them with pass through heat sinks. Some units have automatic gas pressure....sets the proper pressure for the consumables being used, the torch length, as well as for changing incoming pressure. Ease of use, reliability, cut quality and low operating cost are the key features of the major brand plasma systems that set them apart from the low cost alternatives.

- Industrial plasma system torches are specifically designed to work with the power supplies they are used with....these are not "universal, one size fits" all torches. To get the best performance from a plasma torch....cooling, energy density, ease of use, as well as electrical power ramp up/down and gas flows are all extremely critical to the end result. Putting a plasma torch on a power supply that was not specifically designed with it will not allow performance to its full advantage.

- Major brand plasma systems after sale service and warranty is covered by a large distributor network and are backed by a factory and staff that will support the plasma long after the warranty has expired. Documentation...operators manuals and service manuals are available for each unit...and often are over 100 pages long. All good information for use, performance, troubleshooting issues and have detailed parts diagrams as well as many pages of suggested operating specs for both hand and mechanized cutting.

-Safety is of key importance as well....plasma cutting operates at higher voltage levels as compared to most welding processes. Many low cost import systems have exposed high voltage connections....and have internal and external wiring that simply does not pass safety codes (CSA and CE certifications) in many regions of the world. Be careful of safety issues when choosing some of the importers private labeled systems!

-Power supply and cutting capability specifications are correct on most major brand systems....this means you can expect to cut at the thicknesses and speeds that the units are advertised at. The cut charts listed in the manuals will provide excellent cut quality....and the duty cycle ratings are conservative. (duty cycle ratings require an ambient temperature, an amperage and a load voltage rating in order to be accurate...most of the imports simply supply a duty cycle percentage without backing it up with data).

-Torch consumable sets are designed to provide the best cut quality in conjunction with long life. One set of consumables will not cut all materials with the best cut quality.....so the major manufacturer offers choices. As an example on one major manufacturers 65 Amp plasma: it can use fine cut consumables (under 45 amps on less than 10 gauge) 45 amp shielded (under 45 amps for up to 1/2" with excellent edge squareness) and 65 amp shielded consumables for max thickness and speed. You can choose to use the 65 amp consumables for all cutting...or you can fine tune cut quality on thinner materials as advised by the cut charts.

Bottom line....the major brand units cut metal....like all plasma cutters. They cut metal very well, with extremely long consumable life...and will be around for your children to inherit with the rest of your quality tools.

It is really the decision of the buyer....spend less up front at the time of purchase for a tool, or spend a bit more and purchase a high quality tool that will (over time) cost far less (cost of ownership).

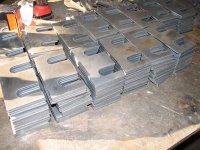

Attached pics are all cut with a major brand 85 amp plasma that can use either a hand torch or a machine torch (quick change, no tools required) so you can switch from mechanized cutting to hand cutting in seconds. The first two pics show 1/8" shims being cut (over 825 of them) ....the third pic is some 1/4" steel parts with tab and slot fitup, the last are some 3/16" aluminum. All of the parts were cut with a single set of 45 amp consumables...over 900 starts.....with plenty left to go!

Jim Colt

Generally speaking....all plasma cutters will cut metal....and in some cases that is enough to satisfy some hobbyist applications. The differences that you will see if you step up to the more costly (to buy.....less costly to use) major brand systems:

- Power supplies are of the latest technology. They are designed, reliability tested and built to survive in industrial environments under the rigors of production use. The primary goal of an industrial plasma power supply is to be operator friendly, reliable and to support the torch design that is used with the power supply.

-Internal circuit boards are (on some brands) are conformally coated (so shop dust does not short them) and are mounted vertically (so shop dust does not build up on them). Cooling fans operate on demand only (so less dust is pulled through the unit). There is a "clean side, dirty side" design that keeps critical components out of the fan flow area and cools them with pass through heat sinks. Some units have automatic gas pressure....sets the proper pressure for the consumables being used, the torch length, as well as for changing incoming pressure. Ease of use, reliability, cut quality and low operating cost are the key features of the major brand plasma systems that set them apart from the low cost alternatives.

- Industrial plasma system torches are specifically designed to work with the power supplies they are used with....these are not "universal, one size fits" all torches. To get the best performance from a plasma torch....cooling, energy density, ease of use, as well as electrical power ramp up/down and gas flows are all extremely critical to the end result. Putting a plasma torch on a power supply that was not specifically designed with it will not allow performance to its full advantage.

- Major brand plasma systems after sale service and warranty is covered by a large distributor network and are backed by a factory and staff that will support the plasma long after the warranty has expired. Documentation...operators manuals and service manuals are available for each unit...and often are over 100 pages long. All good information for use, performance, troubleshooting issues and have detailed parts diagrams as well as many pages of suggested operating specs for both hand and mechanized cutting.

-Safety is of key importance as well....plasma cutting operates at higher voltage levels as compared to most welding processes. Many low cost import systems have exposed high voltage connections....and have internal and external wiring that simply does not pass safety codes (CSA and CE certifications) in many regions of the world. Be careful of safety issues when choosing some of the importers private labeled systems!

-Power supply and cutting capability specifications are correct on most major brand systems....this means you can expect to cut at the thicknesses and speeds that the units are advertised at. The cut charts listed in the manuals will provide excellent cut quality....and the duty cycle ratings are conservative. (duty cycle ratings require an ambient temperature, an amperage and a load voltage rating in order to be accurate...most of the imports simply supply a duty cycle percentage without backing it up with data).

-Torch consumable sets are designed to provide the best cut quality in conjunction with long life. One set of consumables will not cut all materials with the best cut quality.....so the major manufacturer offers choices. As an example on one major manufacturers 65 Amp plasma: it can use fine cut consumables (under 45 amps on less than 10 gauge) 45 amp shielded (under 45 amps for up to 1/2" with excellent edge squareness) and 65 amp shielded consumables for max thickness and speed. You can choose to use the 65 amp consumables for all cutting...or you can fine tune cut quality on thinner materials as advised by the cut charts.

Bottom line....the major brand units cut metal....like all plasma cutters. They cut metal very well, with extremely long consumable life...and will be around for your children to inherit with the rest of your quality tools.

It is really the decision of the buyer....spend less up front at the time of purchase for a tool, or spend a bit more and purchase a high quality tool that will (over time) cost far less (cost of ownership).

Attached pics are all cut with a major brand 85 amp plasma that can use either a hand torch or a machine torch (quick change, no tools required) so you can switch from mechanized cutting to hand cutting in seconds. The first two pics show 1/8" shims being cut (over 825 of them) ....the third pic is some 1/4" steel parts with tab and slot fitup, the last are some 3/16" aluminum. All of the parts were cut with a single set of 45 amp consumables...over 900 starts.....with plenty left to go!

Jim Colt