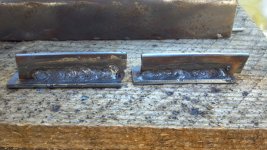

I did some more T-joints today, and a few lap joints. Just a bunch more junk, of course, but I finished this weld and when I went to strip the slag, the whole thing came off in one big clean strip. I looked at it and I thought, "You know. That looks like a weld." I still have some issue with undercut at the top, and probably a whole lot more issues that I don't even see, but this is probably the best looking joint I've done so far.

View attachment 285917

My 7014 is 3/32" instead of 1/8" like my 6011, so it's not apples to apples, but man the 7014 seems to run really nice. The 6011 is really hard to keep the slag out of and to make a nice smooth bead. I should try some of that 7018 I have; I hear it's pretty smooth too.