Shield Arc

Super Member

First off let me start with the disclaimer! I don't recommend this one little bit. But I just wanted to see what I could get away with!

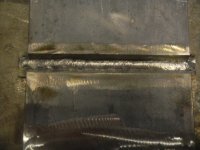

I took some 1/2-inch plate, cut 45-degree angles on them. Placed them 3/16-inch apart. Took a hand full of 1/8-inch Lincoln Excalibur 7018. This rod has been setting on the bench for years in an open can, never seen the inside of a rod oven. I placed the rod in a welding rod can, and filled the can with water. Poured the water out. Set the Lincoln V350-pro to 120-amps, 0.0 on the arc force. Before using each rod, I placed them in the stinger and grounded them out on the welding table. Once the water started to boil out of the rod I used my glove to dry off the rod. I ran one rod after the other on this test plate, only stopping to clean. Cut the coupons into 3/8-inch strips, and did a side bend test.

I don't think they came out to bad.

I took some 1/2-inch plate, cut 45-degree angles on them. Placed them 3/16-inch apart. Took a hand full of 1/8-inch Lincoln Excalibur 7018. This rod has been setting on the bench for years in an open can, never seen the inside of a rod oven. I placed the rod in a welding rod can, and filled the can with water. Poured the water out. Set the Lincoln V350-pro to 120-amps, 0.0 on the arc force. Before using each rod, I placed them in the stinger and grounded them out on the welding table. Once the water started to boil out of the rod I used my glove to dry off the rod. I ran one rod after the other on this test plate, only stopping to clean. Cut the coupons into 3/8-inch strips, and did a side bend test.

I don't think they came out to bad.

Attachments

-

7018 water.JPG237.6 KB · Views: 377

7018 water.JPG237.6 KB · Views: 377 -

7018 dry 1.JPG229.9 KB · Views: 355

7018 dry 1.JPG229.9 KB · Views: 355 -

7018 dry 2.JPG239.9 KB · Views: 293

7018 dry 2.JPG239.9 KB · Views: 293 -

7 root.JPG233.6 KB · Views: 544

7 root.JPG233.6 KB · Views: 544 -

7 2 pass.JPG225.5 KB · Views: 341

7 2 pass.JPG225.5 KB · Views: 341 -

7 3pass.JPG241.6 KB · Views: 316

7 3pass.JPG241.6 KB · Views: 316 -

7 layout.JPG233.5 KB · Views: 409

7 layout.JPG233.5 KB · Views: 409 -

7 cut.JPG237.1 KB · Views: 344

7 cut.JPG237.1 KB · Views: 344 -

7 ready.JPG234.7 KB · Views: 463

7 ready.JPG234.7 KB · Views: 463 -

7 bend.JPG228.7 KB · Views: 374

7 bend.JPG228.7 KB · Views: 374 -

7 perfect.JPG236.5 KB · Views: 375

7 perfect.JPG236.5 KB · Views: 375