Shield Arc

Super Member

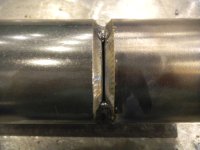

You don't have to, it is just a suggestion. It just insures that you get 100 + % penetration. It is a form of open root welding.Carl, if I read your post correctly in comparison to the photos, are you recommending that I lift the hooks up slightly from the surface I'm going to weld them to? If so, what do recommend, 1/16th or so?

Oh I forgot, if you decide to gap the hooks. 1/16" is plenty, or even just use the same wire you will be using to weld the hooks on with. .035"?