Shield Arc

Super Member

Did you see I welded my hooks on with 7018? I'm not afraid of Mig / wire feed, but I've probably run more spools of wire than most here have seen. A Mig welder in the wrong hands does give me concern, that is why I try to help as much as I can.Couldn't agree more. That is why the suggestion of avoiding MIG and going with stick was made earlier.

One just DOESN'T want those hooks snapping off at an inopportune or critical time.

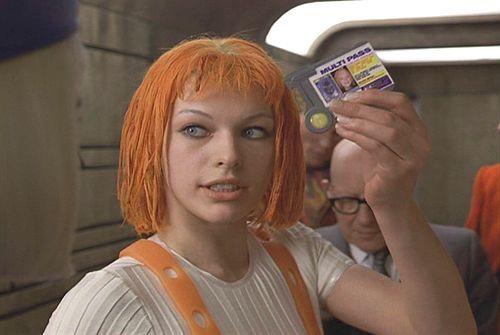

You didn't want those hooks to go anywhere did you!Multi pass !!!!!!!!:thumbsup: