mjncad

Super Member

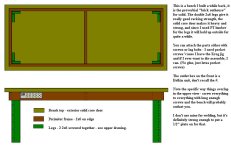

welder table from Northern Tool + Equipment

the spec on this shows a max thickness of 2 mills. Like a garbage bag...

I'd say Northern's web-wienies screwed up on the thickness. It's probably 12GA sheet metal at best.

Now that VG has gone to china, its Grip on locking pliers for me now, I wont buy another from Stronghand when I can get Grip Ons for the same cost. GRIP-ON TOOLS: THE LARGEST RANGE OF LOCKING TOOLS WORLDWIDE Grip-on is also the OEM for Snap-on's locking pliers if they arent available in local stores. Snap-on Tools

I never heard of Grip-On until today. Thanks for the link to their website.