You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will this work? If not what will?

- Thread starter dwadec21

- Start date

/ Will this work? If not what will?

#1

joshuabardwell

Elite Member

Just to be clear, the problem is that you have some stripped bolt holes in your tractor frame, and you want to secure the loader frame to the tractor frame permanently with welds?

Just to be clear, the problem is that you have some stripped bolt holes in your tractor frame, and you want to secure the loader frame to the tractor frame permanently with welds?

This is correct. I don't want to remove the loader frame from the tractor frame, to strip the powder coating, because i don't want to chance completely losing "Bolt #3's" threads. And I fear not having a good ground by just connecting the ground clamp to the tractor frame alone because I assume that continuity between the two pieces of material is not present because of the layer of powder coat that is sandwiched between the two.

joshuabardwell

Elite Member

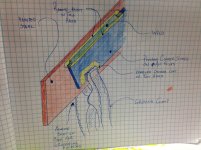

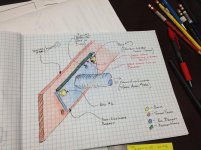

I think your assumption about grounding between the pieces is correct. You could test this with a multimeter if you really cared to, but grinding clean both sides and then clamping to them should create the necessary continuity, since one side of the clamp will be touching each of the pieces. Here's an alternative, that will save you from grinding off very much powdercoat from the loader frame: grind clean the back surface of the frame, then clamp as depicted in the drawing. Grind clean the paint/powdercoat from the joint, then strike an arc on the frame side of the joint and carry the puddle over to the loader frame, creating a tack. Once the pieces are tacked together, there will be ample continuity.

Bolt #3 will be grounding the two pieces together. Wire wheel where you are going to weld. The powder coating will be slag when you run the weld. Another method would be tapping the existing holes for a bigger bolt. If bolt #3 has questionable threads; do the first holes and then back #3 out and do that one oversize also.

joshuabardwell

Elite Member

I think you're trying to avoid welding out of position by only putting a single bead on the top, but I do have to wonder whether a single bead will provide enough strength to replace the missing bolts. It's surely not how a manufacturer would have welded it up.

oldnslo

Super Member

I think you're trying to avoid welding out of position by only putting a single bead on the top, but I do have to wonder whether a single bead will provide enough strength to replace the missing bolts. It's surely not how a manufacturer would have welded it up.

I have to agree with Josh that only welding the top will not be strong enough. Are these blind holes or can you drill them through and use a bolt and nut to hold the frame on? If something goes wrong with the tractor and you have to split it, would this frame prevent you from doing that?

Bolt #3 will be grounding the two pieces together. Wire wheel where you are going to weld. The powder coating will be slag when you run the weld. Another method would be tapping the existing holes for a bigger bolt. If bolt #3 has questionable threads; do the first holes and then back #3 out and do that one oversize also.

The the interior of the bolt holes in the loader frame are coated with powder coat as well.

I thought about tapping also. The bolts actually go through the frame and bolt into the engine block. be impossible to tap. Unless they have a tap set for that purpose that I don't know about, which is completely possible, hah.

I think you're trying to avoid welding out of position by only putting a single bead on the top, but I do have to wonder whether a single bead will provide enough strength to replace the missing bolts. It's surely not how a manufacturer would have welded it up.

I have to agree with Josh that only welding the top will not be strong enough. Are these blind holes or can you drill them through and use a bolt and nut to hold the frame on? If something goes wrong with the tractor and you have to split it, would this frame prevent you from doing that?

You guys think it would be a good idea to weld the entire perimeter? My thoughts were that if I were to have to split the frame in the future it would be alot easier to grind one bead of weld on the top for removal of the loader mount instead of the entire perimeter. But at the same time I dont want the FEL to fall off.

They are blind holes. The bolts go through the actual tractor frame and fasten into the engine block or one of the engines appurtenances.

From:

Tap and die - Wikipedia, the free encyclopedia

Bottoming tap or plug tap

The tap illustrated in the top of the image has a continuous cutting edge with almost no taper — between 1 and 1.5 threads of taper is typical. This feature enables a bottoming tap to cut threads to the bottom of a blind hole. A bottoming tap is usually used to cut threads in a hole that has already been partially threaded using one of the more tapered types of tap; the tapered end ("tap chamfer") of a bottoming tap is too short to successfully start into an unthreaded hole. In the US, they are commonly known as bottoming taps, but in Australia and Britain they are also known as plug taps.

Tap and die - Wikipedia, the free encyclopedia

Bottoming tap or plug tap

The tap illustrated in the top of the image has a continuous cutting edge with almost no taper — between 1 and 1.5 threads of taper is typical. This feature enables a bottoming tap to cut threads to the bottom of a blind hole. A bottoming tap is usually used to cut threads in a hole that has already been partially threaded using one of the more tapered types of tap; the tapered end ("tap chamfer") of a bottoming tap is too short to successfully start into an unthreaded hole. In the US, they are commonly known as bottoming taps, but in Australia and Britain they are also known as plug taps.