Jarrett

Silver Member

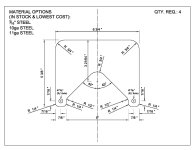

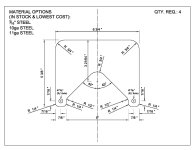

I'm making a bracket to mount my 15 gal sprayer to my ZTR mower and I need some steel sheet cut out. I already have some material and can do it myself with the few tools that I have (portaband, grinder, etc.), but I don't really have the time to spend on cutting these out. I got prices from a few local shops here, but they were all way more than I'm care to spend. One shop quoted $3+ for material and $80 labor (laser). I'm not saying they're out of line. These are large shops with large machines, so their overhead just to start the machines up is high I'm sure. I don't know of any other shop locally that is a smaller operation with smaller machines and lower operating costs. Does anyone here do this line of work or know of any place online that provides these services? I've attached a picture of the bracket.