Thanks to everyone for the advice and feedback. If I'm over-heating the tube, then I think it is most likely a combination of factors. Being new to TIG, my travel speed is probably not as fast as it could be. I also often have beads that are slightly concave, which I have been attributing to not enough filler, but it could also be excessive heat. Anyway, I'm sure it's something that will improve with practice.

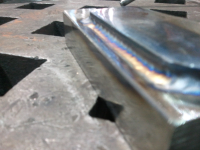

I have had some success using the torch to bend the tubes by welding beads on them. (Zero success using the torch to heat the tube without melting it.) What worked best so far is to weld a U-shape, with about 1" of weld along the corners of the tube and then a bead perpendicular to the length of the tube. I'm sure an H shape would work too. If I just weld on the corners, or just weld across the tube, I don't seem to get any movement at all, really, but if I do them together, it does the trick okay.

Hypothetically, how would I heat the tube if I wanted to cause it to twist? My guess: barberpole spiral all the way around.