dieselcrawler

Elite Member

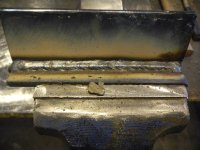

Gonna be doing some repairs to some Brush Crusher grapples at work today. Part of which will include welding on some extra gusseting. I have always used 6013 since I was a kid learning to weld, for clean materials and nice finish. However, there is a full can of 7018 there and no so much of 6013, so I am gonna play with it for the experiance. The few times I have tried to use 7018, it seems hard to strike an arc with and just not nearly as easy to use as 6013. Will report back later... and will post a few pix.

Also have a lot of 6010...

Feedback and advice welcome...

Also have a lot of 6010...

Feedback and advice welcome...