CDN Farm Boy

Veteran Member

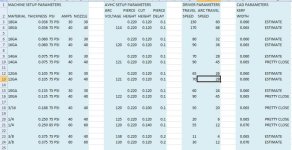

Can anyone provide me to a link to a chart for settings for a plasma cutter?

I'm using an Everlast PowerPlasma 50 with hand-held S45 torch. I got the machine for Christmas and just finally got to fire it up today. Literature that came with it isn't helpful. I'd have thought it would have a chart like on the inside of my mig, ie: Thickness - amps - air - travel speed. Or is there some other way to figure out what settings to use?

Thanks

I'm using an Everlast PowerPlasma 50 with hand-held S45 torch. I got the machine for Christmas and just finally got to fire it up today. Literature that came with it isn't helpful. I'd have thought it would have a chart like on the inside of my mig, ie: Thickness - amps - air - travel speed. Or is there some other way to figure out what settings to use?

Thanks