Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,197

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

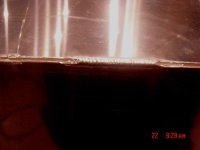

I was interested in the discussion about welding an item "tight" vs "weep hole". I was working on my gate yesterday and was looking at it, thinking about water and wondering if there was any inside it. My gate is welded "tight".

Drilled a hole and water poured out. It poured a lot more, that's how it looked by the time I dug the camera out. Recommend some folks drill drain holes in their "tight" implements and see what happens. Of course a little water in there might be more curiosity than problem (except near salt).

(EDIT: DELETED 2nd PIC with the large pee-stream BECAUSE i found where water can get in that one. The first one was welded tight, no nek'd eye visible entry points.

Drilled a hole and water poured out. It poured a lot more, that's how it looked by the time I dug the camera out. Recommend some folks drill drain holes in their "tight" implements and see what happens. Of course a little water in there might be more curiosity than problem (except near salt).

(EDIT: DELETED 2nd PIC with the large pee-stream BECAUSE i found where water can get in that one. The first one was welded tight, no nek'd eye visible entry points.

Attachments

Last edited: