joeu235

Platinum Member

- Joined

- Mar 27, 2014

- Messages

- 724

- Location

- Little River, TX

- Tractor

- John Deere 4020 / 6403 / 317 Ford 5600

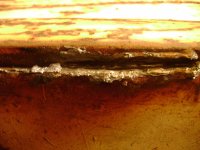

I bought a Hypertherm 30XP plasma cutter last week. So for I've used it mostly coping 2 3/8 drill stem, pattern cutting pipe joints that meet at a 60 degree angle. This thing is awesome. I find it amazing that compressed air and electricity can cut through 3/16 pipe effortlessly.