Cord

Veteran Member

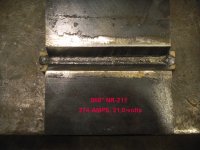

Currently about 2/3 the way through a 25lb spool of NR-232 and my tips are toast. The wire is .068 which apparently isn't a very common size. I have a new .035 liner and I'm thinking of shelving the 232 for a big project and then going to a smaller, more common wire. Dealer has suggested NR-211, but I wanted to double other opinions of this wire before I pull the trigger.

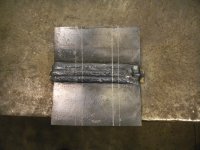

Looking for a all-position, flux-core wire. Low splatter and easy slag removal is important. Generally clean my surfaces before welding, but copper coated doesn't rust on the spool either.

Looking for a all-position, flux-core wire. Low splatter and easy slag removal is important. Generally clean my surfaces before welding, but copper coated doesn't rust on the spool either.