npalen

Elite Member

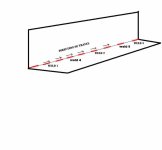

Ordered a 60" 1/2"x4" weld-on replacement cutting edge for my 48" bucket.

Titan 6�" Bucket Cutting Edge Hardened 1�55 Carbon Steel 1/2" Tractor Loader | eBay

My question is what to do with the ends. The pictures show the cutting edge wrapped around and up the ends of the bucket a couple inches. I think that I can duplicate that by heating with the rosebud torch and pounding the ends up but not sure if I can do it as well as the original.

The existing up-wrap is worn blunt so would kinda like to replace it but the other option might be to cut the existing cutting edge off while leaving the wrapped vertical portion on each end. The new piece would be laid in flush with the outside edge of the vertical portion.

Could use some feedback on how to approach this. Thanks in advance.

Titan 6�" Bucket Cutting Edge Hardened 1�55 Carbon Steel 1/2" Tractor Loader | eBay

My question is what to do with the ends. The pictures show the cutting edge wrapped around and up the ends of the bucket a couple inches. I think that I can duplicate that by heating with the rosebud torch and pounding the ends up but not sure if I can do it as well as the original.

The existing up-wrap is worn blunt so would kinda like to replace it but the other option might be to cut the existing cutting edge off while leaving the wrapped vertical portion on each end. The new piece would be laid in flush with the outside edge of the vertical portion.

Could use some feedback on how to approach this. Thanks in advance.