Dadnatron

Veteran Member

I have 2 pieces of equipment that I need to modify for connection to a hammerstrap.

Long story short, I've snapped a 2" x 1 1/4" drawbar with the 'orange' drag blade in the configuration it is now. I had a thread on here about potentially welding it back together, but ended up going with a new drawbar. http://www.tractorbynet.com/forums/welding/372200-broken-drawbar-chances-pro-welder.html?highlight=

But now, I need to modify my drawbar and implements in order to prevent it from happening again.

I have decided on a Hammerstrap/lunette configuration.

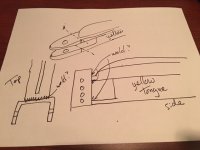

I have a 6yd scraper (yellow) and a 12ft enclosed Killifer (drag blade/land leveler), both of which I need to be able to connect to my hammerstrap.

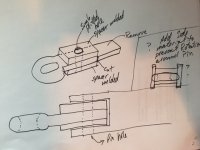

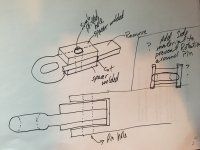

I have thought about simply getting a lunette bar Curt Lunette Ring - Bolt On - 3" Diameter - 22, lbs Curt Lunette Ring C4851 and welding a spacer (perhaps a piece of the old drawbar) to it in order to 'fill space'. Then cut it, drill a big hole, and simply pin it to the implement. This would allow me to move the lunette from scraper to blade and vice versa. All without final welding and cutting on the implements themselves. I'd like to know what you think of this idea. If there are major hurdles to the functionality of that option, then I'd like to know your recommendation about attaching a lunette ring to these implements, disrupting the current connection, to the least possible degree.

I know they are mine... and that a welded lunette ring would likely improve them from here on out, but if I ever sell them, I don't want to have it stop a sale. (this is likely poor and obstructive thinking, but at this moment, I am looking at as many possibilities and options as I am able, prior to "no return" cutting of my implements.)

Long story short, I've snapped a 2" x 1 1/4" drawbar with the 'orange' drag blade in the configuration it is now. I had a thread on here about potentially welding it back together, but ended up going with a new drawbar. http://www.tractorbynet.com/forums/welding/372200-broken-drawbar-chances-pro-welder.html?highlight=

But now, I need to modify my drawbar and implements in order to prevent it from happening again.

I have decided on a Hammerstrap/lunette configuration.

I have a 6yd scraper (yellow) and a 12ft enclosed Killifer (drag blade/land leveler), both of which I need to be able to connect to my hammerstrap.

I have thought about simply getting a lunette bar Curt Lunette Ring - Bolt On - 3" Diameter - 22, lbs Curt Lunette Ring C4851 and welding a spacer (perhaps a piece of the old drawbar) to it in order to 'fill space'. Then cut it, drill a big hole, and simply pin it to the implement. This would allow me to move the lunette from scraper to blade and vice versa. All without final welding and cutting on the implements themselves. I'd like to know what you think of this idea. If there are major hurdles to the functionality of that option, then I'd like to know your recommendation about attaching a lunette ring to these implements, disrupting the current connection, to the least possible degree.

I know they are mine... and that a welded lunette ring would likely improve them from here on out, but if I ever sell them, I don't want to have it stop a sale. (this is likely poor and obstructive thinking, but at this moment, I am looking at as many possibilities and options as I am able, prior to "no return" cutting of my implements.)

Last edited: