284 International

Veteran Member

- Joined

- Jun 28, 2010

- Messages

- 1,464

- Tractor

- International Harvester 284

The school where I teach is working on developing gardening plots for the sixth graders. They don't have a tractor to use, and partly in thanks to my experiences at this forum I am apparently the resident expert on agricultural practices, specifically tractors and their implements. With some of the budget, we picked up this:

(Scroll to the bottom to hear about my trouble with the tractor, the rest is just information and observation)

It is a YM186D, purchased from the original owner who used it to cultivate tomato, onion and strawberry plants. It has extremely brawny side cultivators, as can be seen, that are able to lift the tractor entirely off the ground, and a 3 point cultivator in back. It fires up and runs perfectly. The paint is better than it looks, and the seat is the worst thing cosmetically about the tractor. It's also the most comfortable tractor seat I've ever experienced. I really like the 2 stage air filtration system.

The tractor has 4 44lb suitcase weights up front, actually one more than Yanmar permits according to the manual. It also has wheel weights in back, and I couldn't tell how many, but I think just one per side. The original owner's manual shows there are three total weights available per wheel, an inner mounting flange (20kg or 44lbs), then two weights of 44lbs and 55lbs respectively.

There is also a nifty, but inoperable fuel gauge. It appears to have an LCD screen that indicates the fuel level. It seems like a marvelous source of contaminants when trying to refuel, since it must be placed somewhere while filling the tank, and the diesel-moistened float will certainly collect any and all possible contaminants wherever one places it. Based on the fuel consumption of my other Yanmars, maybe if I replace the battery it will tell me if I should buy 1 gallon of diesel or 2 when I refuel it at the beginning of each school year, whether it needs it or not! :laughing:

I had asked some questions about this model tractor before. I have a 1401D, and the two are fairly close in footprint. The 186D is significantly heavier. I estimate this unit weighs more than my 1401D does with a loader. Compared to a 1401D, it seems everything is heavier. The bracketry for the side cultivators is massive: 1 inch by 2.25 inch bars up front, and massive braces and connections underneath.

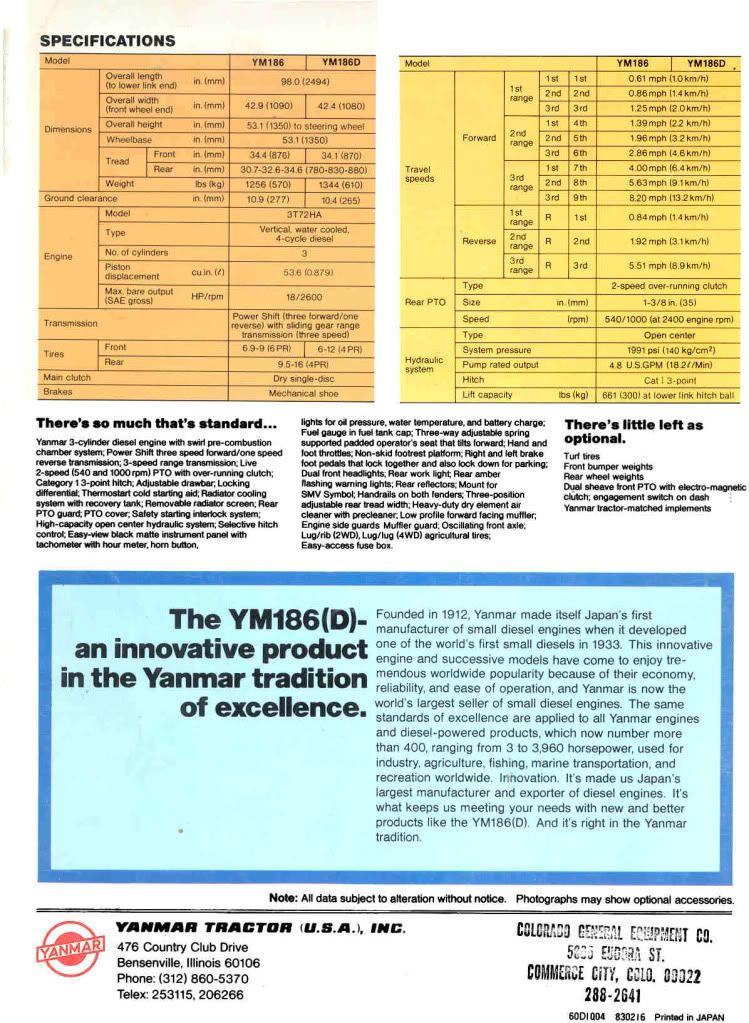

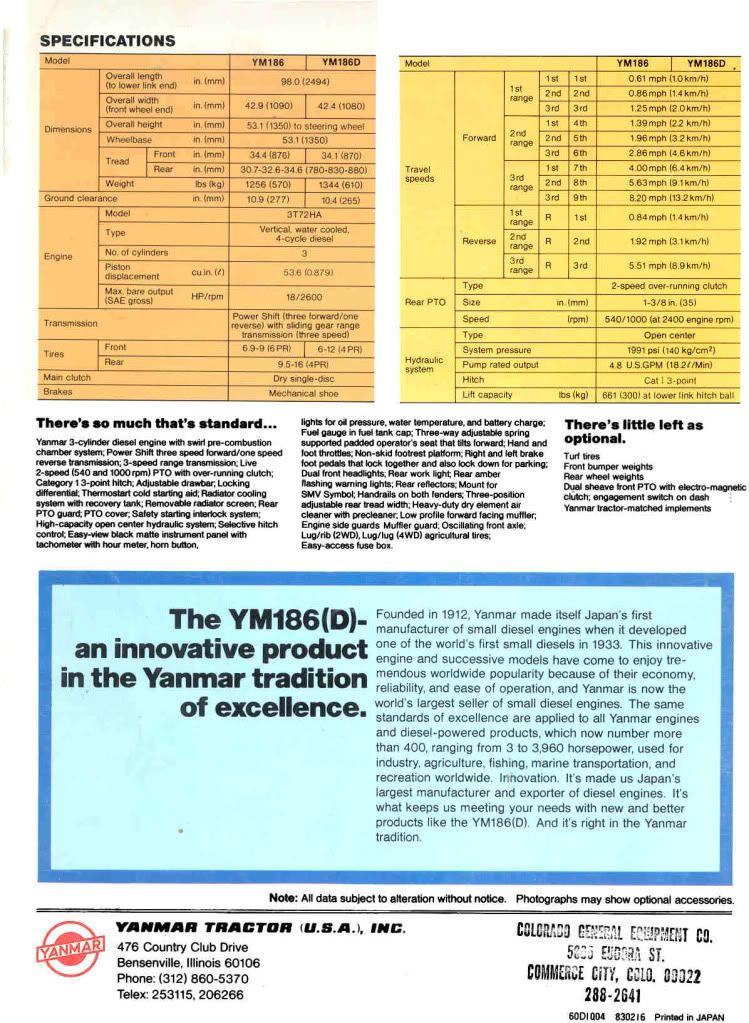

I wouldn't use it to mount a front end loader, but the tractor would break before the brackets. The previous owner did not recall if the tractor's tires were ballasted. I haven't measured three point hitch dimensions yet, but, interestingly, the Yanmar operation manual that came with the tractor calls the 186 a Cat 0 3 point hitch, even though the dimensions given are Category 1. Also, there is some discrepancy between the owner's manual from Yanmar, and their own advertisements: the manual says lift capacity is 926lbs at 24 inches behind the points, while their sales brochure says 661lbs at the balls.

(Special thanks to rScotty for sharing the brochure with me) Either way, the hydraulics on the 186 are extremely powerful, and feel as strong, and certainly quicker acting, as the system on my YM240.

The transmission on this machine is absolutely terrific. I'm officially smitten. The ability to shift up and down on the fly will increase productivity immensely. It addresses any real issue I have, for my purposes, with a manual transmission, while saving the appeal of direct mechanical connection and the resulting efficiency. The motor is a bit disappointing, though. With all of the mass versus the 1401D, the single additional horsepower has a lot more load to carry. It lacks the overpowered for its weight feeling of the 1401D. It's not underpowered, but the 1401D is overpowered, and I was expecting the same feel from this 186D. It doesn't have it.

Compared to my YM240, the lack of low-end torque is dramatic in its absence. I think the two are closer than it initally seems in horsepower, but I have found, as California mentioned in his comparison of these two tractors, the 2 cylinder has much more ability to lug and pull itself back up to the set rpm. I would compare them to a 250cc two stroke dirtbike vs my 515cc 4 stroke. The horsepower numbers are close, but the 3 cylinder 186, like a 2 stroke, has to be kept spun up, while the 2 cylinder 240 will grunt down to where the individual cylinders can be heard popping, then clank its way out. The 3 cylinder is far smoother sounding. With the powershift transmission, I think skillful driving will let this little 15 PTO horsepower tractor play out of its weight class...

****Here is my problem/question, if you're skipping down****

It has a problem, though. It only operates in 2 wheel drive. The front wheel drive system is fine, back to the driveshaft input. Each wheel will spin the driveshaft if the other is held stationary, and spin one another if the driveshaft is secured.

Acting on a tip gleaned from Aaron at Hoye in another thread (Here: http://www.tractorbynet.com/forums/yanmar/91706-1510d-repairs.html) I pulled the 4 wheel drive shift lever (A dreadful nuisance to drive out the roll pin, since there's not enough room to get a punch AND the hammer). Once I got the roll pin out, a 30mm socket pulled the fastener, and I shimmied the shift rod out of the hole, expecting a gush of transmission fluid to follow. It did not, this area is actually open to the bottom on these tractors. Here is what I found:

While I'm not totally sure what it's supposed to look like, I'm sure that the original part is not supposed to have that compound kink in it. (It's also askew in a slight twist, but I couldn't get a good photograph of that aspect.) I straightened it, welded then ground smooth a hairline crack, and put it all back together. It doesn't want to operate, though. I was still in decent clothes (welding, I know) and didn't want to crawl on my back to look underneath.

The operation manual doesn't cover any lubrication points on the 4wd shifting mechanism. Since whatever issue initially bent the shift fork is still in there, it needs to be rectified so the shift lever can move the shift fork and the drive coupling.

How do I check to make sure the shift lever is engaging the shifter fork? How can I figure out where the binding is occuring in the shift linkage? Should I blast up into the area with carb cleaner to spray out the cobwebs, rust, and dirt that has accumulated there, then go wild with WD-40? What is correct procedure to isolate and treat these symptoms? Thanks, as always, for the help.

(Scroll to the bottom to hear about my trouble with the tractor, the rest is just information and observation)

It is a YM186D, purchased from the original owner who used it to cultivate tomato, onion and strawberry plants. It has extremely brawny side cultivators, as can be seen, that are able to lift the tractor entirely off the ground, and a 3 point cultivator in back. It fires up and runs perfectly. The paint is better than it looks, and the seat is the worst thing cosmetically about the tractor. It's also the most comfortable tractor seat I've ever experienced. I really like the 2 stage air filtration system.

The tractor has 4 44lb suitcase weights up front, actually one more than Yanmar permits according to the manual. It also has wheel weights in back, and I couldn't tell how many, but I think just one per side. The original owner's manual shows there are three total weights available per wheel, an inner mounting flange (20kg or 44lbs), then two weights of 44lbs and 55lbs respectively.

There is also a nifty, but inoperable fuel gauge. It appears to have an LCD screen that indicates the fuel level. It seems like a marvelous source of contaminants when trying to refuel, since it must be placed somewhere while filling the tank, and the diesel-moistened float will certainly collect any and all possible contaminants wherever one places it. Based on the fuel consumption of my other Yanmars, maybe if I replace the battery it will tell me if I should buy 1 gallon of diesel or 2 when I refuel it at the beginning of each school year, whether it needs it or not! :laughing:

I had asked some questions about this model tractor before. I have a 1401D, and the two are fairly close in footprint. The 186D is significantly heavier. I estimate this unit weighs more than my 1401D does with a loader. Compared to a 1401D, it seems everything is heavier. The bracketry for the side cultivators is massive: 1 inch by 2.25 inch bars up front, and massive braces and connections underneath.

I wouldn't use it to mount a front end loader, but the tractor would break before the brackets. The previous owner did not recall if the tractor's tires were ballasted. I haven't measured three point hitch dimensions yet, but, interestingly, the Yanmar operation manual that came with the tractor calls the 186 a Cat 0 3 point hitch, even though the dimensions given are Category 1. Also, there is some discrepancy between the owner's manual from Yanmar, and their own advertisements: the manual says lift capacity is 926lbs at 24 inches behind the points, while their sales brochure says 661lbs at the balls.

(Special thanks to rScotty for sharing the brochure with me) Either way, the hydraulics on the 186 are extremely powerful, and feel as strong, and certainly quicker acting, as the system on my YM240.

The transmission on this machine is absolutely terrific. I'm officially smitten. The ability to shift up and down on the fly will increase productivity immensely. It addresses any real issue I have, for my purposes, with a manual transmission, while saving the appeal of direct mechanical connection and the resulting efficiency. The motor is a bit disappointing, though. With all of the mass versus the 1401D, the single additional horsepower has a lot more load to carry. It lacks the overpowered for its weight feeling of the 1401D. It's not underpowered, but the 1401D is overpowered, and I was expecting the same feel from this 186D. It doesn't have it.

Compared to my YM240, the lack of low-end torque is dramatic in its absence. I think the two are closer than it initally seems in horsepower, but I have found, as California mentioned in his comparison of these two tractors, the 2 cylinder has much more ability to lug and pull itself back up to the set rpm. I would compare them to a 250cc two stroke dirtbike vs my 515cc 4 stroke. The horsepower numbers are close, but the 3 cylinder 186, like a 2 stroke, has to be kept spun up, while the 2 cylinder 240 will grunt down to where the individual cylinders can be heard popping, then clank its way out. The 3 cylinder is far smoother sounding. With the powershift transmission, I think skillful driving will let this little 15 PTO horsepower tractor play out of its weight class...

****Here is my problem/question, if you're skipping down****

It has a problem, though. It only operates in 2 wheel drive. The front wheel drive system is fine, back to the driveshaft input. Each wheel will spin the driveshaft if the other is held stationary, and spin one another if the driveshaft is secured.

Acting on a tip gleaned from Aaron at Hoye in another thread (Here: http://www.tractorbynet.com/forums/yanmar/91706-1510d-repairs.html) I pulled the 4 wheel drive shift lever (A dreadful nuisance to drive out the roll pin, since there's not enough room to get a punch AND the hammer). Once I got the roll pin out, a 30mm socket pulled the fastener, and I shimmied the shift rod out of the hole, expecting a gush of transmission fluid to follow. It did not, this area is actually open to the bottom on these tractors. Here is what I found:

While I'm not totally sure what it's supposed to look like, I'm sure that the original part is not supposed to have that compound kink in it. (It's also askew in a slight twist, but I couldn't get a good photograph of that aspect.) I straightened it, welded then ground smooth a hairline crack, and put it all back together. It doesn't want to operate, though. I was still in decent clothes (welding, I know) and didn't want to crawl on my back to look underneath.

The operation manual doesn't cover any lubrication points on the 4wd shifting mechanism. Since whatever issue initially bent the shift fork is still in there, it needs to be rectified so the shift lever can move the shift fork and the drive coupling.

How do I check to make sure the shift lever is engaging the shifter fork? How can I figure out where the binding is occuring in the shift linkage? Should I blast up into the area with carb cleaner to spray out the cobwebs, rust, and dirt that has accumulated there, then go wild with WD-40? What is correct procedure to isolate and treat these symptoms? Thanks, as always, for the help.