Stonehaller

Platinum Member

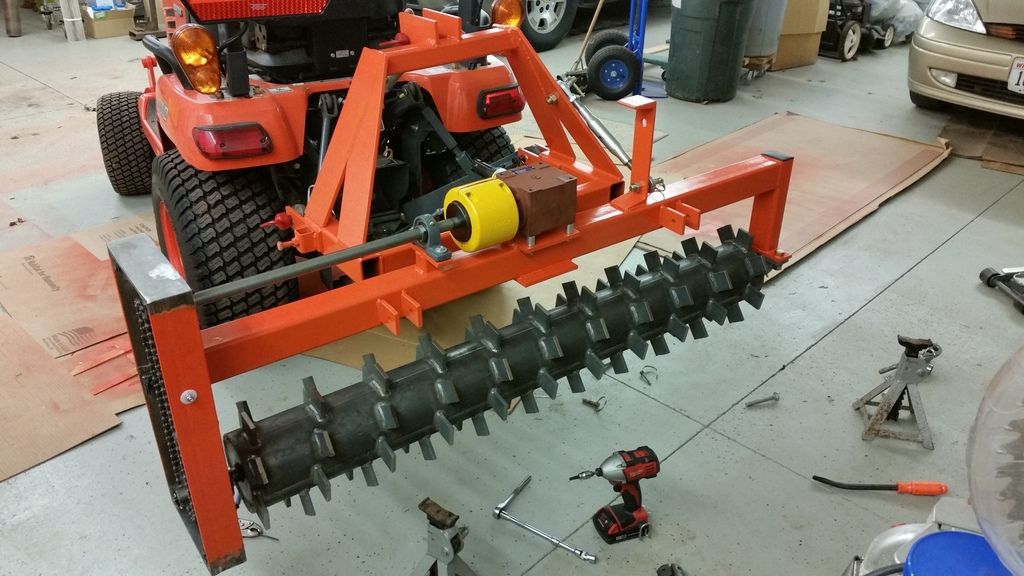

Is there any reason to choose a Lovejoy setup vs Universal joint?

I can get either setup for about the same cost. The LJ would add a bit of cushioning during startup vs the solid connection of the UJ.

The Lovejoy coupling you picked out will not handle the load. Your tractor has about 18 PTO HP. At 540 RPM, 18 HP is 175 lb-ft of torque. The coupling is only rated 680 in-lbs or about 57 lb-ft.

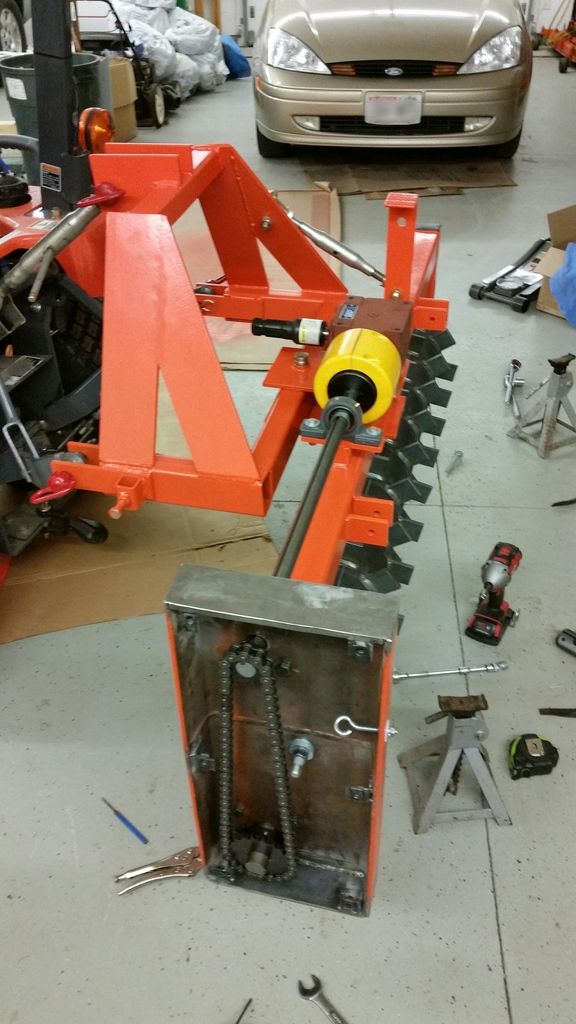

The universal joint has a high enough rating, but the thing with a universal joint is that you need two joints to handle both axial and angular misalignment. Two joints also maintain constant angular velocity. You would still need a second bearing to support the shaft near the sprocket.

I see Surplus Center has some 60 pitch roller chain couplings that will handle the torque, but are only rated for 500 RPM. Also, I do not see a cover for the 60 pitch chain couplings so you have to ask them as you would need a cover to keep the dirt out.

Are you planning on a slip clutch or shear pin in the PTO shaft?