astep

New member

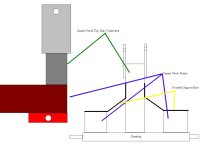

i would like learn how to weld by creating a 3 pt. implement to use for turning my garden over for planting. i have been following several posts on this website and have joined to have some of my questions answered. although, i'm only 16, i work after-school on a dairy farm and am regularly around tractors, therefore i have a somewhat decent knowledge of tillage equip. using a 12' row of c tines cut in half from my boss's old cultimulcher, i would like to create a 3pt. tool to prep our garden. this implement will be used on my dad's JD 4310 on our 2.5 acres. to make it slightly easier, i could start off with a drawbar, yet was unsure if welding it to square stock frame would be a weak bond- two 6' rows of 5 c tines might be a tough pull for the 4310. the pic attached better explains what I would like to do. would it be better to incorporate the two bottom pins into the square stock frame? thanks for any criticism

astep

astep