robstaples

Gold Member

I would like some welding advice on the carelessness with my new thumb. I was pulling out 5" buckthorn stumps ( live-fresh cut) . Grabbed them at the top and pinched with my foot peddle and wiggle and pulled toward me (Must have been the fatal mistake for crack 1).. and Voila broken bucket. Pinched one on the right end of bucket too (crack 2). It was fun shaking the dirt out of them, etc, until I notice the arc in the bucket edge.

I have MIG and TIG available and thought to v-grove the cracks and multi pass the fill. I have 308 and tri-gas for stainless, also ( wondering about a harder fill material). What I know little about is the pre heat, slow cool, and the best wire to use with xxx ( is it cast steel??)( I'm absolutely terrible with stick)

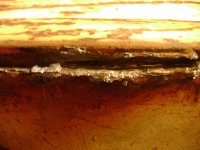

My damage is below. the cracked is in 1/2" material. Crack 1 and crack 2

Your Suggestions would be appreciated:

I have MIG and TIG available and thought to v-grove the cracks and multi pass the fill. I have 308 and tri-gas for stainless, also ( wondering about a harder fill material). What I know little about is the pre heat, slow cool, and the best wire to use with xxx ( is it cast steel??)( I'm absolutely terrible with stick)

My damage is below. the cracked is in 1/2" material. Crack 1 and crack 2

Your Suggestions would be appreciated: