flingwing1969

Platinum Member

- Joined

- Jun 2, 2008

- Messages

- 692

- Tractor

- LS G3038, JD GT275, and Bolins H16

Yes, my G3038H.

These are the only FF I have on my tractor. I've only had one time when one of my ag style held pressure - can't recall the circumstances but I know it had to do with my rear remotes and hooking up my hoe, a quick tap with a board on the tip of the ag and the pressure was relieved immediately - just a drop of oil so it wasn't much being held in.

When I crack the line to relieve pressure in it, there is never a spurt or a his or anything, only a drip or two as I make the connection with the line cracked. I suspect, therefore, that the pressure is being held down the line from the FEL remotes. Again really no pressure, just a completely full line that is not allowing return to the tank.

Yes, I have tried to reconnect immediately after disconnecting and sometimes I can, sometimes I can't.

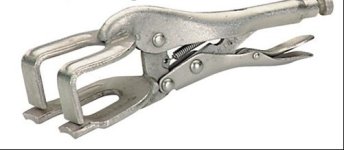

I suspect that, because there is not too much pressure, I might be able to fab a tool to give me mechanical advantage in making the connection without the need for cracking the line fitting. I think I mentioned a friend of mine has an older Bobcat and finds that the FF on it are difficult to connect as well - he made a tool to allow him to complete the connections more easily - and the Bobcat has a switch to relieve pressure and I thought their FF connectors have an internal pressure release as well - push in on the fitting.

Yes, it is puzzling but it is also a fact.

These are the only FF I have on my tractor. I've only had one time when one of my ag style held pressure - can't recall the circumstances but I know it had to do with my rear remotes and hooking up my hoe, a quick tap with a board on the tip of the ag and the pressure was relieved immediately - just a drop of oil so it wasn't much being held in.

When I crack the line to relieve pressure in it, there is never a spurt or a his or anything, only a drip or two as I make the connection with the line cracked. I suspect, therefore, that the pressure is being held down the line from the FEL remotes. Again really no pressure, just a completely full line that is not allowing return to the tank.

Yes, I have tried to reconnect immediately after disconnecting and sometimes I can, sometimes I can't.

I suspect that, because there is not too much pressure, I might be able to fab a tool to give me mechanical advantage in making the connection without the need for cracking the line fitting. I think I mentioned a friend of mine has an older Bobcat and finds that the FF on it are difficult to connect as well - he made a tool to allow him to complete the connections more easily - and the Bobcat has a switch to relieve pressure and I thought their FF connectors have an internal pressure release as well - push in on the fitting.

Yes, it is puzzling but it is also a fact.