morpheous71

New member

Hi All

New to the board. I recently bought a Mahindra 4025 which I'm already in love with.

Added a few mod's, sun canopy (basketball backdrop), aux. lights, grapple (versatech).

So the problem I'm having is this;

Installed the grapple and decided to run it off the power beyond with a joystick controller/switch. Used a directional solonoid valve and like I said I by passed the cut into the powerbeyond then went through the valve (4 way) then out other side to the PTO, then the other two lines go down to the grapple for open and close. Took forever to figure out the switch, push button 3 way, but I finally got it and hooked everything up and it worked fine. Had a few leaks which had to be fixed up but I got that done. I thought everything was fine until I tried the lever for the 3 point hitch. It didn't work.....so I on hooked everything again set it up the way it originally was and then tried the lever again and now the up/down for the hitch works??? The PTO works either way....so I have limited understanding on this but I'm figuring I have too much load on the hydraulics or maybe not enough fluid getting to the back because the lines I used are alittle smaller and the valve holes are definitely more constrictive....??? Can anyone help with this problem, hopefully my description makes sense. I'll take some pic's now and then attach them to the inquiry????

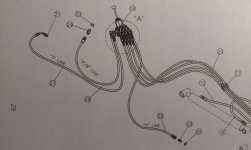

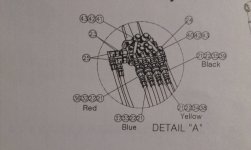

Here is the original set-up.:confused2:

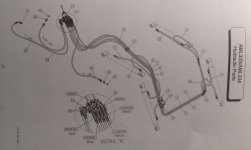

New pic's, showing the set-up but the lines have temp. been switched back to original loader spec's.

New to the board. I recently bought a Mahindra 4025 which I'm already in love with.

Added a few mod's, sun canopy (basketball backdrop), aux. lights, grapple (versatech).

So the problem I'm having is this;

Installed the grapple and decided to run it off the power beyond with a joystick controller/switch. Used a directional solonoid valve and like I said I by passed the cut into the powerbeyond then went through the valve (4 way) then out other side to the PTO, then the other two lines go down to the grapple for open and close. Took forever to figure out the switch, push button 3 way, but I finally got it and hooked everything up and it worked fine. Had a few leaks which had to be fixed up but I got that done. I thought everything was fine until I tried the lever for the 3 point hitch. It didn't work.....so I on hooked everything again set it up the way it originally was and then tried the lever again and now the up/down for the hitch works??? The PTO works either way....so I have limited understanding on this but I'm figuring I have too much load on the hydraulics or maybe not enough fluid getting to the back because the lines I used are alittle smaller and the valve holes are definitely more constrictive....??? Can anyone help with this problem, hopefully my description makes sense. I'll take some pic's now and then attach them to the inquiry????

Here is the original set-up.:confused2:

New pic's, showing the set-up but the lines have temp. been switched back to original loader spec's.

Last edited: