KennyG

Elite Member

Under the principle that you should share your mistakes in case others are as careless as you, I just did a little unexpected work on my 2010 JD 2320. Those of you who have these machines know about the infamous engine driveshaft universal joints. I have been scrupulous in greasing mine and the tractor now has 820 hours. I was servicing it in preparation for installing my Original Tractor Cab for the winter and had an attention lapse. I was greasing the joints and, as usual I was using a large screwdriver in the rear yoke to rotate the shaft (I know it isn't the preferred way to do it but it's what I've always done.) I wasn't paying attention and stuck the screwdriver in the front side of the yoke instead of the back and broke the grease zerk off.

After a bit of a tantrum I took the joint apart and found it came apart easily because there was just enough movement of the yoke on the transmission spline to separate it. I extracted the broken zerk, put a new one in and it went back together fairly easily.

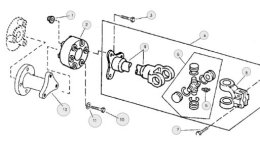

After this, I thought about what I would have done if I had messed up the joint. With a little searching it seems that the Moog 410 U-joint is the correct replacement. It seems to differ from the original in that it has the zerk fitted to an end cap.

https://www.amazon.com/Moog-410-Universal-Joint/dp/B008M2FPOE

(Summit has it cheaper but the Amazon site has a better picture.) This got me thinking that using the Moog part would make greasing this a lot easier. Has anyone done this? To replace the front joint, it appears there are bolts that attach a flange to the flywheel. Is this how the shaft is removed? It would seem the rear joint would still have to be separated to get enough clearance to pull the shaft out.

With over 800 hours my u-joints are in very good condition and I usually don't do proactive part replacement (I'm more of a run to failure type) but the potential to make the lubrication much easier has me thinking of changing them out at the next service. Any opinions on this?

After a bit of a tantrum I took the joint apart and found it came apart easily because there was just enough movement of the yoke on the transmission spline to separate it. I extracted the broken zerk, put a new one in and it went back together fairly easily.

After this, I thought about what I would have done if I had messed up the joint. With a little searching it seems that the Moog 410 U-joint is the correct replacement. It seems to differ from the original in that it has the zerk fitted to an end cap.

https://www.amazon.com/Moog-410-Universal-Joint/dp/B008M2FPOE

(Summit has it cheaper but the Amazon site has a better picture.) This got me thinking that using the Moog part would make greasing this a lot easier. Has anyone done this? To replace the front joint, it appears there are bolts that attach a flange to the flywheel. Is this how the shaft is removed? It would seem the rear joint would still have to be separated to get enough clearance to pull the shaft out.

With over 800 hours my u-joints are in very good condition and I usually don't do proactive part replacement (I'm more of a run to failure type) but the potential to make the lubrication much easier has me thinking of changing them out at the next service. Any opinions on this?